Best Drying Equipment for Fortified Rice/Instant Rice/Artificial Rice – Fluidized Bed Dryer

Fortified Rice

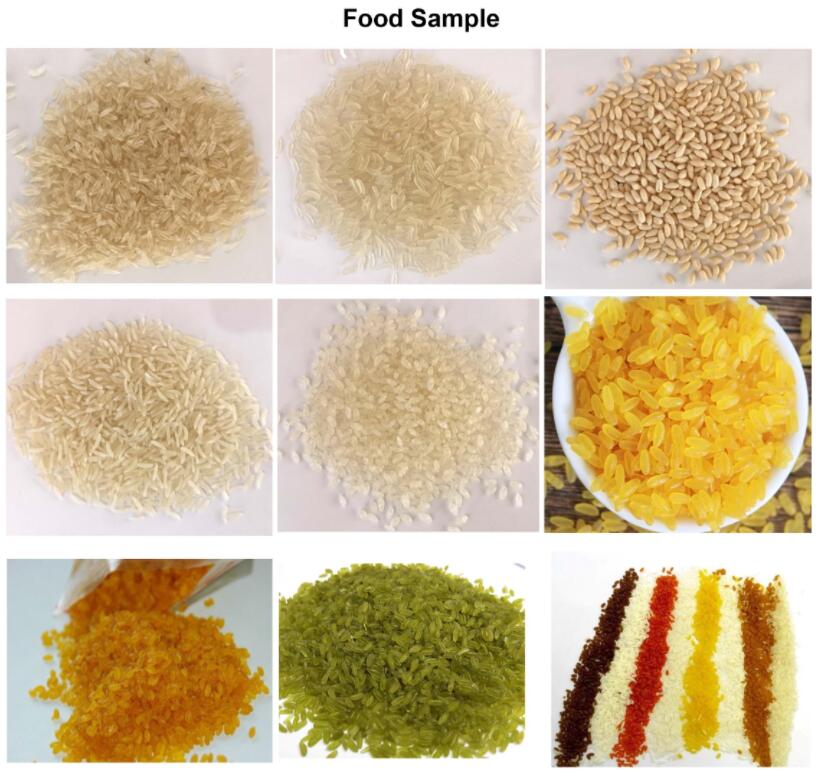

Broken rice grains are ground into rice flour and then mixed with water and the required nutrients to make a dough. The fortified dough is then passed through an extruder to produce fortified rice grains.

Rice fortification is basically the process of increasing the amount of important micronutrients in rice by adding vitamins and minerals to improve its nutritional quality and thus obtain health benefits. Fortified rice provides a variety of essential nutrients that benefit the health of consumers.

Hot extrusion is supported by a strong evidence base and shows good consumer acceptance. Fortified rice looks, cooks and tastes the same as non-fortified rice.

Nutritious Rice

Raw Materials: Widely sourced, can make full use of local natural resources (corn, sweet potatoes, beans, starch raw materials), broken rice and micronutrients. , low cost and a variety of flavors

Products with different flavors and functions can be developed according to the preferences and needs of different consumer groups.

For example, nutritious rice can produce buckwheat rice for diabetic patients by customers.

Arroz instantáneo

No matter what kind of rice it is, or what the raw materials are, the mixture of raw materials and water is made into rice shape through hot extrusion technology. Instant rice is placed in appropriate hot water and can be eaten in about 15 minutes, which is convenient and fast. Now many countries sell this kind of instant rice, and the market is very wide. For example, Haidilao self-heating rice, etc.

However, in production, the taste of rice is very important, which is closely related to the extrusion technology and drying technology of rice, especially the drying technology. Today we will introduce a machine that is very popular in the rice industry and has a drying effect far higher than that of ordinary ovens-fluidized bed dryer.

Due to the particularity of rice, it has a relatively high water content in production. In order to achieve better taste and storage requirements, drying needs to be comprehensive and uniform. In order to reduce the cost of the production line, some manufacturers only equip customers with a small oven, which is far from meeting the requirements, and it should be said that it does not meet the requirements of a high-quality rice.

Take the 1000kg/h rice production line as an example:

- Two fluidized bed dryers are needed. The moisture content of rice coming out of the first fluidized bed is about 17%, and the moisture content of rice coming out of the second fluidized bed is about 12%, which meets the normal storage requirements.

- The rice is constantly rolling and jumping in the fluidized bed, so that the rice is fully dried and the drying efficiency is improved. The traditional oven is stationary and the moisture is dried slowly. A larger oven is needed instead, which is more expensive.

- In the constant comparison, the rice tastes better after using the fluidized bed and then cooking

For more information, please contact: