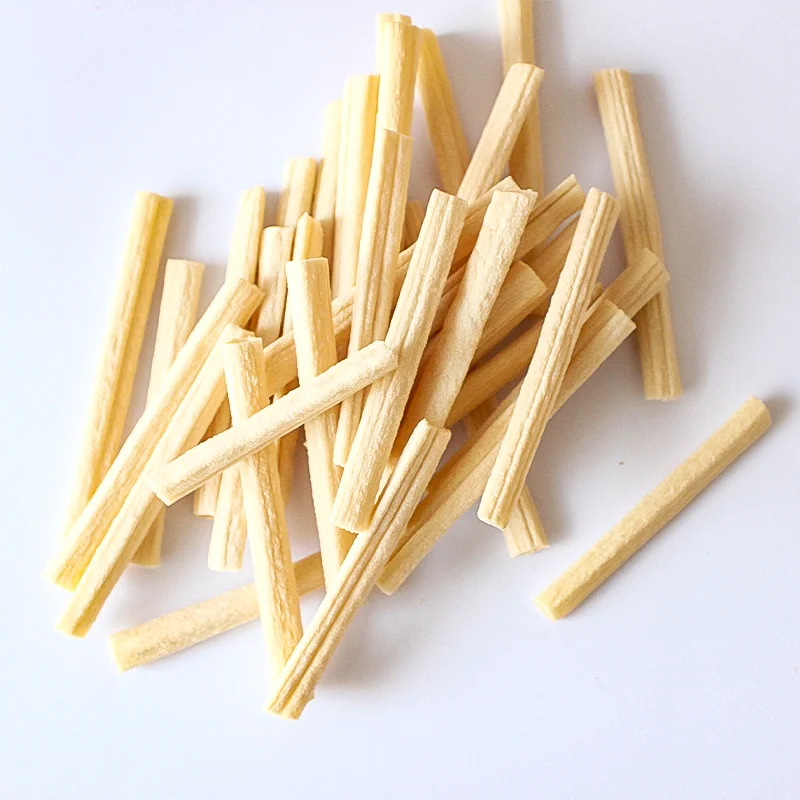

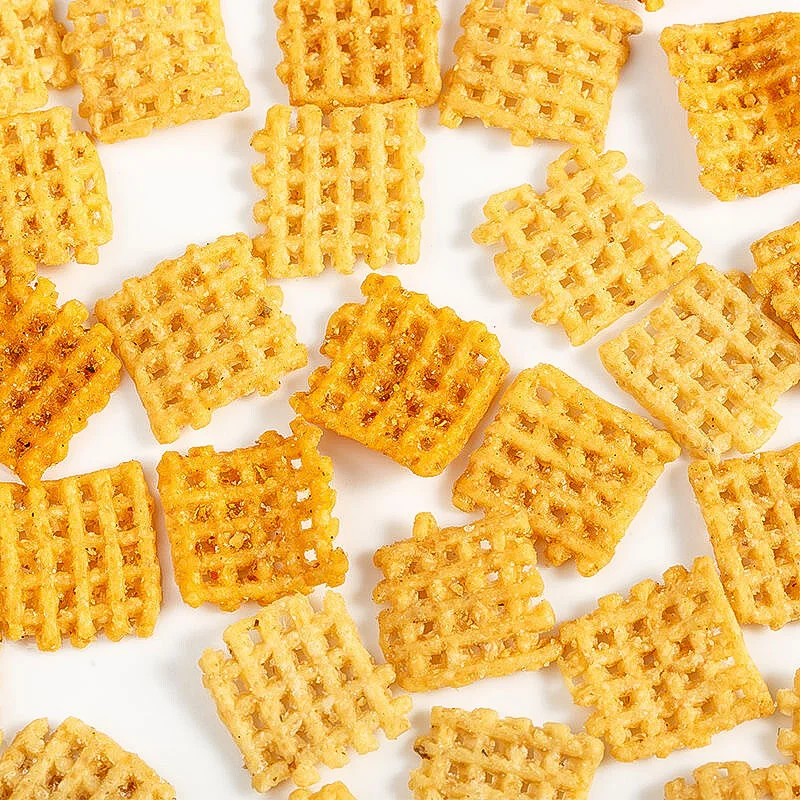

Samples Made By Extrusion Machinery

Fried flour snack is a traditional classic snack food. The raw material is usually corn flour, rice flour, wheat flour, etc. And a single raw material or a combination of multipul raw materials can be used. The traditional production process is steam cooking. The new flour snack is made by extrusion technology, which makes the process simpler and more controllable. The fried flour snack produced is of stable quality and a wide variety.

The flour snack extrusion production line process includes:

raw material mixing, extrusion cooking/expansion, forming, frying, seasoning and packing.

The grain flour and water are blended. Then the mixture is processed in a specially designed extruder. Extrusion-cooking is processed under correct temperature, shear force, residence time to form extrudate with desired texture. Extrudate is shaped and cut through different holes of the extruder die. Immediately after shaping, it is further fried. The frying temperature and time are automatically controlled. The automatic deoiling system will fully separate the excess oil from the fried snack. According to market demand, the seasoning roller can be used to sprinkle salt or sugar on food.

The whole extrusion fried snacks food machinery includes raw material mixer, conveyors, twin-screw extruder, chiller, batch/belt fryer, deoiler, oil circulation system, seasoning machine, packing machine, etc. Whether you need a machine, a whole food production line, or expand your production capacity, we have the advantages of professional knowledge and production experience to escort you.

Capacity&Solution

| Output | Installed Power | Installed Space (m) | Food Name |

| 100-150 kg/h | 41 kw | 17(L) x 2.3(W) x 2.9(H) | Crunchy, sticks, bugles, shell, spiral/screw |

| 200-250 kg/h | 77 kw | 20(L) x 2.3(W) x 2.8(H) | |

| 350-400 kg/h | 122 kw | 21(L) x 3(W) x 3(H) |

Request A Quote

Get Your Proposal

Best Food Solution

Subscribe For Offers

Subscribe for early access offers, discounted rates, and you can cancel at any time.