How To Setup Pani Puri Factory ?

Pani Puri is a popular fast food in Bangladesh, India, Nepal, and Pakistan.

It is also known as Golgappa in northern India.

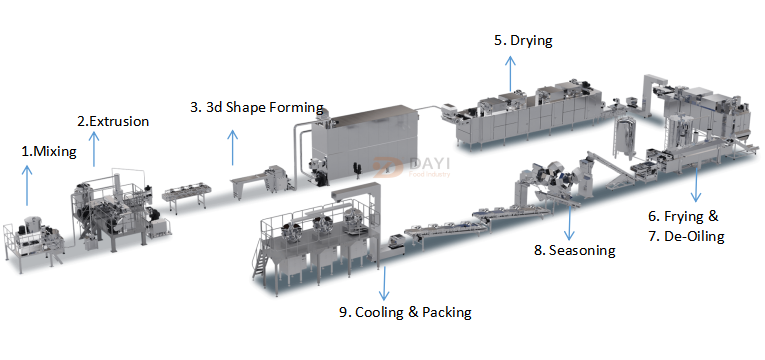

In Pani Puri or Golgappa factories, the complete industrial processing is standard and continuous to ensure the quality and hygiene:

Raw material (wheat, millet, etc.)→Mixing→Extrusion→Shape Forming→Drying→Frying

I. Mixing

The cereal flour is first mixed with water and other materials (like pepper, oil, etc.) in fast speed mixer .

II. Extrusion

Then it is feed into the extruder.

The extruder is normally specially designed.

It is different with other puffed food twin extruders.

The extrusder works with slower speed, with lower pressure, lower temperature, but bigger pressing power, so the material is finally formed into a kind of colloid dough . The extrusion process is crutial as it effects the final mouth feel taste, and the shape forming. The non-appropriate extrusion produces puni puri with hard mouth feel, or oily mouth feel, or failed to puff into balls when fry,

III. Shape Forming

Two big sheets are extruded from the extruder. They together come into the next step–pressing machine. It cut round puni puri slice from the big sheets.

1)The roller cutter is specially designed so that the the material won’t stuck to the roller.

2)Besides, it should also ensures that the edge of round plates are kneaded together firmly, so it won’t seperate during frying.

3)Also, the kneading area on the edge should not effect the mouhth feel.

IV. Drying

Drying process is to remove the moisture from the puni puri slices/pellets. After proper drying process:

1) The puni puri slices/pellets can be kept for long time without sticking together.

2) The puni puri slices/pellets can be kept for long time without crack on surface.

3) Also, the dried puni puri is easily inflated to a ball shape under the heated oil.

V. Frying

If you directly do frying in your factory.

We normally advise the continuous frying machine with external oil heating device. It provides very accurate frying temperature.

1) Fried food continues to go out, and new fried materials continue to enter.

The gain and loss of heat are maintained in a state of dynamic balance.

Along the fried mateial gradually go out, the oil temperatrue won’t rise up suddenly.

Along the cool new material gradually comes in, the oil temperature won’t be pulled down suddenly.

So the oil temperature is always kept at a certain setting value.

So the frying result is stable and uniform.

2) The frying pot is not heated by heater directly.

The oil is pumped out to an external heating device to be heated there, then is pumped back. The oil temperature is remained during circulation.

In direct heating method, when the frying temperature is set to 120 degrees, due to the inertia, although the heater stops to heat once the oil achive the set value, there is still residual heat in the fire chamber to continue heating the oil, so the oil will exceeds 120 degrees.

| Salida | Potencia instalada | Espacio instalado (m) | Alimentación | Price Range (different configuration) |

| 100-120 kg/h | 109 kw | 36(Largo) x 2,4(Ancho) x 2,9(Alto) | Pani puri pellets | USD70000-USD130000 |

| 150-200 kg/h | 124kw | 42(L) x 2.4(W) x 2.9(H) | Pani puri pellets | USD90000-USD150000 |

| 200-300 kg/h | 138 kw | 47(largo) x 2,4(ancho) x 2,9(alto) | Pani puri pellets | USD150000-220000 |

| 400-500 kg/h | 160 kw | 59 (largo) x 2,4 (ancho) x 2,9 (alto) | Pani puri pellets | USD200000-380000 |

Dayi has been in food extrusion industry since 1996.

Welcome to consult or send inquriy to us.