Why is our Vinci extruder the first choice for producing fryums pellets?

Why is our Vinci extruder the first choice for producing fryums pellets?

-

What are fryums pellets:

Please see the picture below. They are very popular in some countries.

2d/3d Pellets shapes.

-

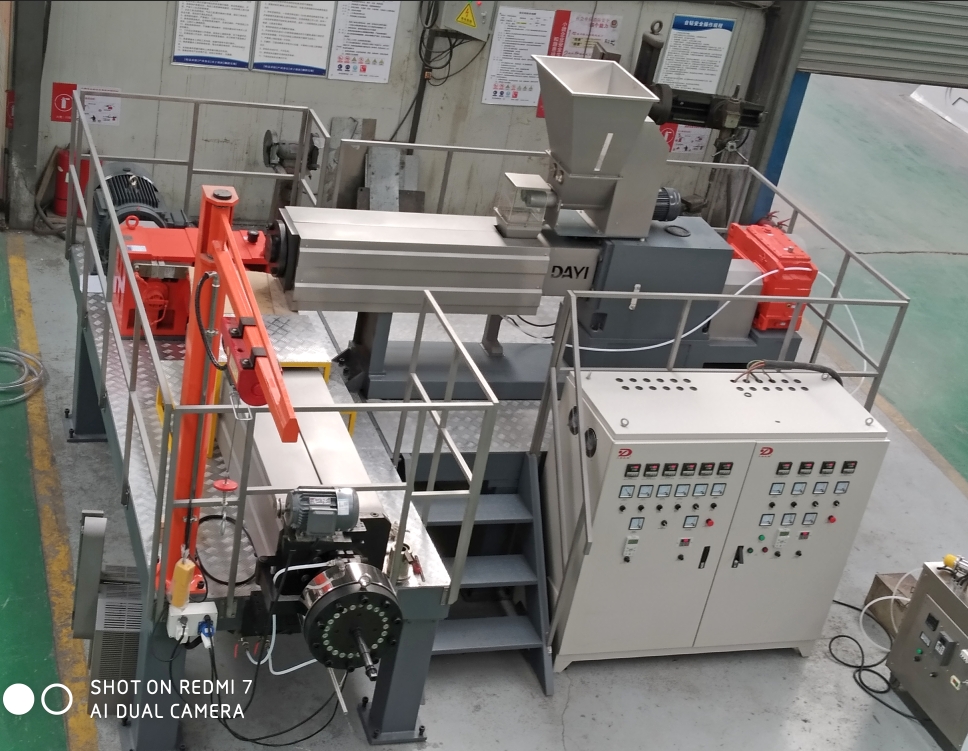

The picture below is our Vinci extruder:

Our Vinci extruder is composed of a twin-screw extruder and a single-screw extruder.

The twin-screw extruder is high temperature and high pressure, which can pre-cook the raw materials well. In this case, the raw materials change the structure of the flour under the action of high temperature, high pressure and high shear of the twin-screw extruder, which can better expand the secondary. Then the material enters the single-screw extruder from the twin-screw extruder for molding. The temperature and pressure of the single-screw extruder are not so high, which can better provide a better shape for fryums pellets.

Some suppliers produce this product using only a single-screw extruder or a twin-screw extruder, but the effect of fryums pellets is somewhat different from that produced by our VINCI extruder. This has a lot to do with cooking, molding and drying. For example, after frying, the taste is crispier, the texture is more delicate, and the shape is more beautiful.

In order to be more competitive and advertise more, some customers use high temperature baking instead of frying. The promotion point is health, which is also very good. We can provide you with different solutions.

This time we mainly introduce the ripening and molding process of the extruder. The drying process is also very important. We can describe it next time. Different shapes of fryums pellets use different auxiliary machines.

For more information, please contact: