Differences among various textured vegetable proteins

Differences Among Various Textured Vegetable Proteins

Textured vegetable protein is also called TVP, or meat analogue. It is a kind of healthy food nowadays, and can be cooked into various delicious dishes with good nutrients.

As known from the name, TVP is made from the vegetable protein. In different areas, there are different vegetable protein options on market according to the features, planting habits, price etc. The common and economic vegetable proteins include soya protein, wheat protein, peanut protein, peas protein, and customers may also use seaweed protein.

After choosing the suitable raw materials, raw materials are then processed by extrusion technology. After extrusion, the plant proteins were through similar changes–the final products are called TVP or meat analogue .

According to the different extrusion technologies, protein sources, additive materials, temperatures, the final products show different features. So when mentioning “meat analogue” or “TVP”, different people may have different conceptions on that. To I put some information as blow to explain the several main different TVP/meat analogues. Hope they are helpful.

| A | B |

C |

|

|

|

|

|

|

|

1. Texture: -More puffed texture. -They are mainly called soya chunks, soya badi, soya nuggets. |

1. Texture:

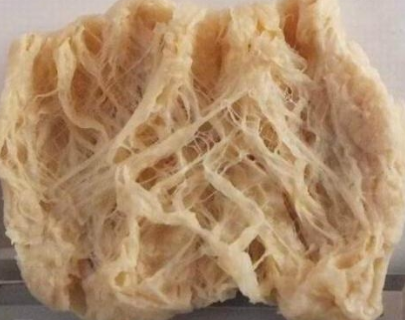

-Fine fibrous textures. Has a meat-like texture. -We call it dry fibrous textured protein.

|

1. Texture: -Fine fibrous textures. Has the most meat-like texture. -It is called High Moisture TVP |

| 2.Material application:

Soya/pea/chickpeas/wheat/peanut protein meal etc., water, starch |

2.Material application:

Wheat protein meal, soya protein isolate, water, starch. Lower extrusion temperature. |

2.Material application:

Wheat protein meal, soya protein isolate, more water, starch. Lowest extrusion temperature. |

| 3.Storage and Market:

Dry condition for easy storage, consumers need to soak them into water before cooking (re-hydration) |

3.Storage and Market:

Dry condition for easy storage, consumers need to soak them into water before cooking (re-hydration) |

3.Storage and Market:

Wet condition, so need to be stored in cool room, and quickly distributed to local restaurants or consumers. No need re-hydration before cooking. |

| 4. types of extruders used in TVP food industry

Extruded by normal twin screw extruder. |

4.types of extruders used in TVP food industry

Extruded by lengthened twin screw extruder, and need a cooling process. |

4.types of extruders used in TVP food industry

Extruded by longest twin screw extruder, and need a cooling process. |

Welcome to contact us if you are interested in soya chunks/badi/nuggets making machine or fibrous TVP making machine.

Edited by Jana