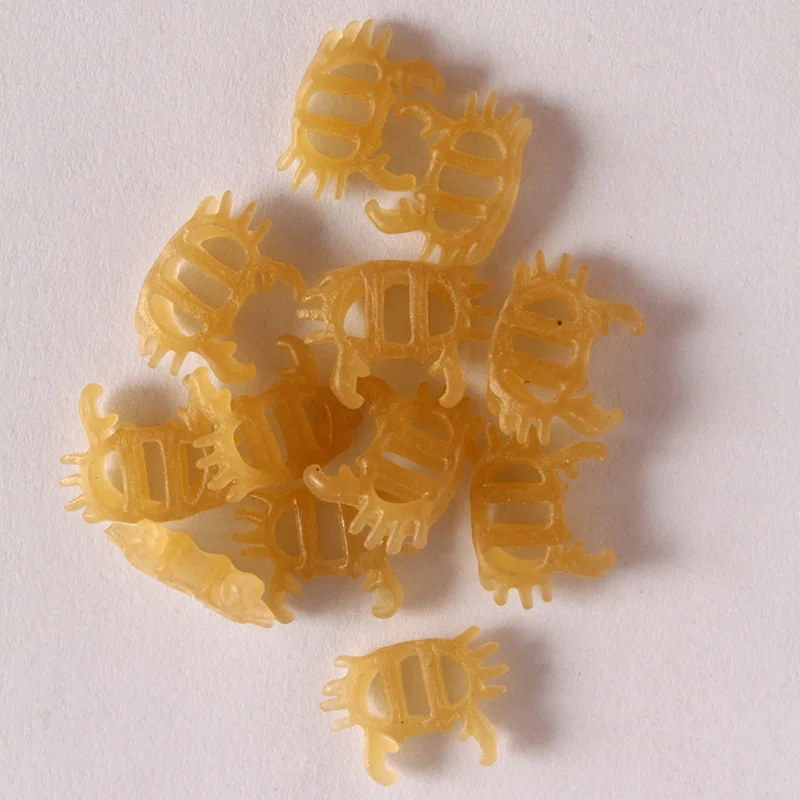

Samples Made by Extrusion Machinery

2D expanding snacks are made based on semi-finished 2D snack pellets that are expanded, seasoned and packed in a second phase. Snack pellets are dry, gelatinised semi-finished product. The main raw materials are potato flour, corn flour and other cereal flours. The material blended with water is cooked/extruded/gelatinized through a specially designed extruder, and then immediately shaped, cut, dried, and then made into snack pellets. Pellet snacks are easy to store and transport. After the expanding, it is still fresh. The flavor after expanding (expanding snacks) is light, crunchy and pleasant.

The shells/spirals/tubes/waves/finger papad making machine process includes: raw material blending, extrusion, shape forming and cutting, drying (semi-finished 2D Snack Pellets), frying, seasoning (finished 2D Pellet-Snack), packing.

The shells/spirals/tubes/waves/finger papad making machine process includes: raw material blending, extrusion, shape forming and cutting, drying (semi-finished 2D Snack Pellets), frying, seasoning (finished 2D Pellet-Snack), packing.

Snack manufacturers are working hard to design snack products to enhance consumers’ sensory experience. Through the flexible extrusion, cutting and multi-layer forming processes, snack pellets provide infinite changes and innovations in color, shape and expansion, etc., providing great possibilities for snack manufacturers to explore new products and lead new trends, increasing consumer enjoyment and fun.

No matter the snack food processor or the consumer, they can choose the way they like to continue to expand the snack pellets. This can be achieved by frying, roasting or roasting, air-popping.

Dayi extrusion technology and equipment can realize the optimal combination of raw materials and processes. Snack pellets can be produced with a variety of textures. The improved twin-screw extrusion process is able to handle wide choice of raw materials. Dayi production line can process the raw materials to have the best gelatinization, fine and smooth texture, less oil absorption when expanding, and beautiful shapes.

Whether you need a machine, whole 2D snack pellets production line, or to expand your existing production capacity, we have the advantages of professional knowledge and production experience to support you

| Output | Installed Power | Installed Space (m) | Food |

| 100-150 kg/h | 109 kw | 36(L) x 2.4(W) x 2.9(H) | Fried 2d pellet snacks;

Finger, screw, wheels, grid, letters, tube, plates, etc. |

| 200-250 kg/h | 138 kw | 47(L) x 2.4(W) x 2.9(H) | |

| 350-400 kg/h | 160 kw | 59 (L) x 2.4(W) x 2.9(H) |

Request A Quote

Get Your Proposal

Best Food Solution

Subscribe For Offers

Subscribe for early access offers, discounted rates, and you can cancel at any time.