Samples Made by The Machinery

Corn flakes are made by extrusion process, without frying process, and can be eaten directly or with milk and yoghurt. It has a delicious and crunchy taste and is rich in nutrition.

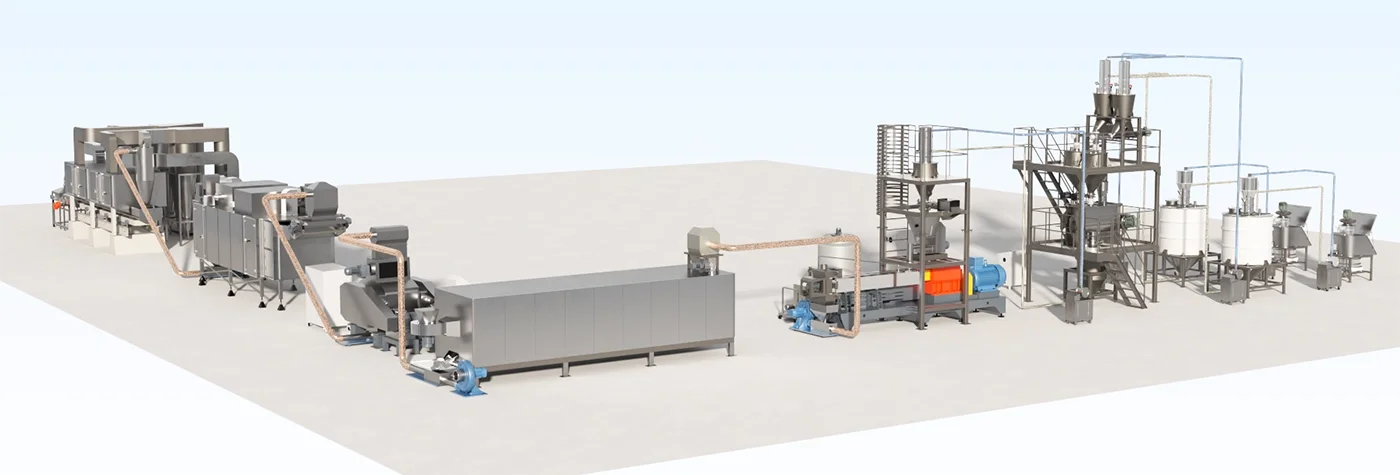

Corn flakes/ breakfast cereal flakes making machine production process:

Ingredients→Mixing→Extrusion→Flaking→Pre-drying→Baking→Spraying→Drying→Cooling→Packing

- Corn flakes production begins with grinding raw corn to make cornmeal.

- After the corn flour is blended with water, it is fed into a specially designed extruder cavity, where it is cooked, kneaded, and mechanically sheared.

- The extrudate is cut with highly rotating knifes to form pellets.

- The extruded balls are rolled into thin sheets by rollers, and then baked at high temperature to produce a crispy texture.

- At this point, the original/plain cornflake is complete.

- According to market demand, seasoning drum can be used to sprinkle salt on the plain corn flakes.

- If plain cornflake is to be coated, it is coated with such as syrup, chocolate, etc. Finally, the flake is dried, cooled and packaged.

- In addition to flakes, by changing the mold, the extrusion technology can also produce round balls, rings and animal shapes to meet diverse market needs.

- In addition, corn, as raw material, can be replaced by other grains, such as wheat flour, rice flour, oat flour, etc. to produce different cereal flake, like rice flake, oat flake, etc. to increase your product variety.

Our corn flakes and breakfast cereal production line make the grain flakes thin and uniform with less material loss, and has precise control over each process.

Whether you need a unit machine, an entire corn flakes production line, or to expand your production capacity, you can rely on our advantage of professional knowledge and superior production experience.

| Output(kg/h) | Installed Power (kw) | Installed Space (m) |

Food Name | Price (USD) |

|---|---|---|---|---|

| 100-160 | 86 | 47 x2 x2.6 | Corn flakes/breakfast cereal | 0.07-0.2 millon |

| 200-250 | 120 | 48x2x2.8 | Corn flakes/breakfast cereal | 0.1-0.26 millon |

| 300-350 | 165 | 49 x2 x3 | Corn flakes/breakfast cereal | 0.16-0.35 millon |

| 500 | 240 | 50 x7 x3 | Corn flakes/breakfast cereal | 0.2-0.8 millon |

| 600-750 | 360 | 53 x9 x3 | Corn flakes/breakfast cereal | 0.28-0.8 millon |

| 900-1000 | 320 | 55×6 x3 | Corn flakes/breakfast cereal | 0.38-1.2 millon |

Request A Quote

Get Your Proposal

Best Food Solution

Subscribe For Offers

Subscribe for early access offers, discounted rates, and you can cancel at any time.