100-150kg/h Fried Potato Stick Namkeen Snacks Making Machine

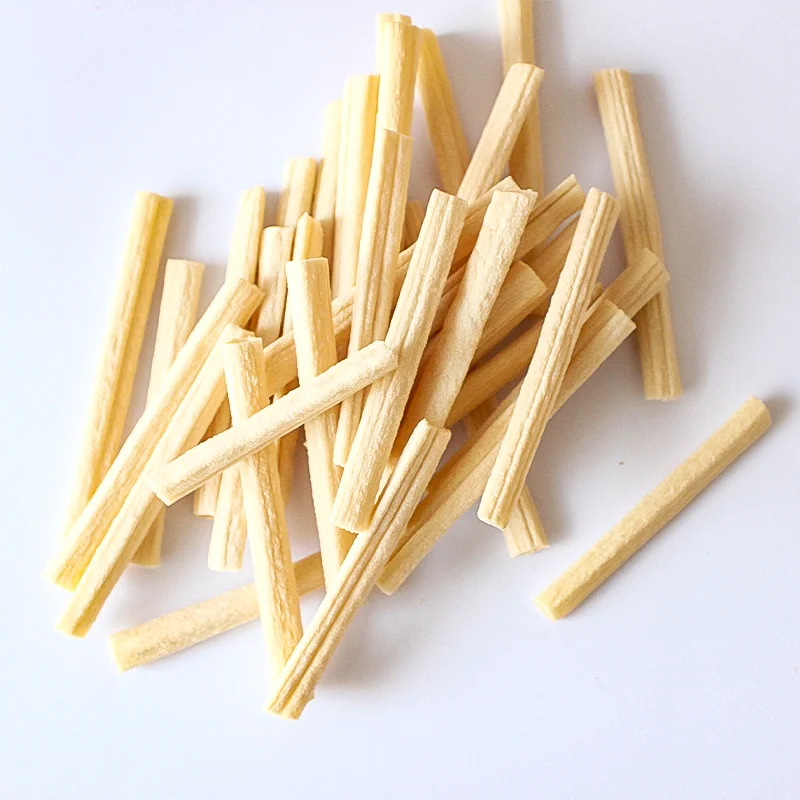

I. Introduction of Potato Sticks

This fried stick snack is made from a combination of grains (wheat flour, rice flour, corn flour and potato flour).

With this snack food making machine, the cereal dough is extruded through multiple die holes of the extruder into rectangular strips, like the cut-potato-strips. The square strips are cut into certain short strips by fast-rotating blades. The short strips then pass through a batch fryer to be fried by batches. The frying machine is equipped with a vibration or centrifugal de-oiler to reduce the residual oil on the sticks. Finally, the production is completed through the automatic seasoning and packing process.

II. Parameters of 100-150kg/h Fried Potato Stick Namkeen Snacks Making Machine

| القدرات | 100-150kg/h |

| الطاقة/الطاقة | -Electric heating: Installed power 41 kw

-Other heating option (Optional): Natural gas/Diesel by burner or steam boiler |

| تثبيت المنطقة | Around 50-80 square meters |

| Multigrain material | Combination of wheat meal, rice meal, corn meal and potato meal |

III. Features

- الانتهاء من الطعام ضمان الجودة: الأمثل قذف حل ممتاز تصميم المعدات, معدات تجهيز ضمان مستوى عال ومستقر الإنتاج.

- ارتفاع الناتج: عالية الإنتاجية المصممة; الحد الأدنى من المواد الخسارة ؛

- أقل من الطاقة: ميكانيكية عالية التنسيق ارتداء منخفضة ؛ الأمثل تدفئة, النقل الحراري والعزل التفاصيل ، منخفضة فقدان الحرارة

- انخفاض تكلفة الإنتاج: تدفق الإنتاج, مراقبة دقيقة لكل عملية

- بسيطة ومنخفضة التكلفة الصيانة: هيكل وحدات ، عملية سهلة. عمر بعد-مبيعات الخدمة

- Material: عالية الجودة الغذائية-مواد آمنة لجميع الاتصال الغذاء جزء

- معدل الفشل: ما يقرب من الصفر الفشل طالما الصيانة الوقائية

IV. The General Flow Chart for Fried Potato Stick Namkeen Snacks

- الخطوة 1: خلط

- Step 2: Extruding

- Step 3: Cutting

- Step 4: Frying

- Step 5: De-oiling

- Step 6: Seasoning

- Step 7: Cooling before packing

- Step 8: Packing

V. Components of Fried Potato Stick Namkeen Snacks Making Machine

- Flour mixer

- Twin screw snack food extruder

- مبرد

- Cutter

- Vibration spreader

- Batch fryer

- De-oiling machine

- Seasoning machine

- Cooling machine

- Automatic packing machine

- نظام التحكم (PLC/أو أداة التحكم خيارات)

- كاملة سيور

- Steam boiler (Optional)

- Burner (Optional)

السادس. المزيد

المرونة

- Twin screw snack food extruder is suitable for a wide range of grain raw materials. Either single grain or multi-grain blends can be processed to extrude foods with different textures.

- The slim stick forming dies are replaceable to extrude snack sticks with different shapes, such as cylindrical or square crunch strips. The snack stick dimensions (width, length etc.) are also various by using different dies, so you can have sticks of all shapes and sizes.

Innovation Potential

With minor adjustments, this stick snack food machinery can also realize the productions of other puffed food recipes.

- For example, by replacing the STICK extrusion die with a SHEET extrusion die, and adding a triangular combination & molding machine, this snack food machinery can produce cone chips/bugles snack.

- By replacing the STICK extrusion die with a SHEET extrusion die, and adding a pressure roller forming machine, this snack food machine can produce fried corn triangle chips/doritos.

As the top food machinery manufacturer in China, DAYI has more than 30 years of experience in the food extrusion field, and can provide your grain food plant with:

Optimal food solutions

Responsible extruded snacks machinery

Reasonable snack food machine price

Continuous technical support.