500-800kg/h High-Meat Dog Chews Food Machinery

I. Introduction of High-Meat Cat/Dog Chews

The secondary extrusion process is specially designed for high meat content cat and dog chews. When the content of fat and fresh meat in the raw material is high, because the moisture and fat in the raw animal raw material will offset the friction in the extruder barrel, making it difficult or even impossible to reach a proper cooking temperature, a twin-screw + single-screw secondary continuous extrusion molding process is required: which firstly use a twin-screw cat/dog food extrusion machinery for precooking, and then continue to use a single-screw cat/dog food extrusion machinery for obtaining high density, chewy, flexible and leathery texture.

Notice:

Dayi engineers will advice the most suitable dog chews food machinery according to your needs.

- When producing bone-shaped, toothbrush-shaped and other die-casting chews, twin-screw extrusion and die-casting processes are required.

- When it is necessary to combine two formulas or colors into one chew, co-extrusion process is required.

- For ordinary single-color or single-recipe pet chews, the single-screw extrusion process is enough.

II. Parameters of 500-800kg/h High Meat Dog Chews Food Machinery

| Capacity | 500-800 kg/h |

| Energy/Power | -Electric heating:

Installed power 205 kw -Other heating option: Natural gas/Diesel by burner or steam boiler |

| Installed Area | 160 square meters |

| Material | Single or combined natural starches from like corn/potato/wheat/rice, dry vegetable powder, dry/wet/frozen animal protein source |

III. The general Flow Chart for High Meat Dog Chews Food Extrusion

- Step 1: Raw materials preparation (degreasing, grinding etc.)

- Step 2: Mixing

- Step 3: First extrusion

- Step 4: Secondary extrusion

- Step 5: Drying

- Step 6: Oil coating and flavor seasoning

- Step 7: Cooling

- Step 5: Measuring and packing

The working process of the secondary continuous cat/dog chews food machinery is as follows:

- Mix evenly the crushed meat products, grain starch (sometimes gluten-free starch), vegetable gum and other raw materials (fruit puree, plant tissue, etc.).

- The mixture is fed into the twin-screw extruder at a constant speed. The twin-screw dog food extrusion machineself-wipes, co-rotates and intermeshes in the multiple processing zones, thereby thoroughly mix the product. Then the cooked and shaped extrudate from the twin-screw dog food extruderis then cut into pellets.

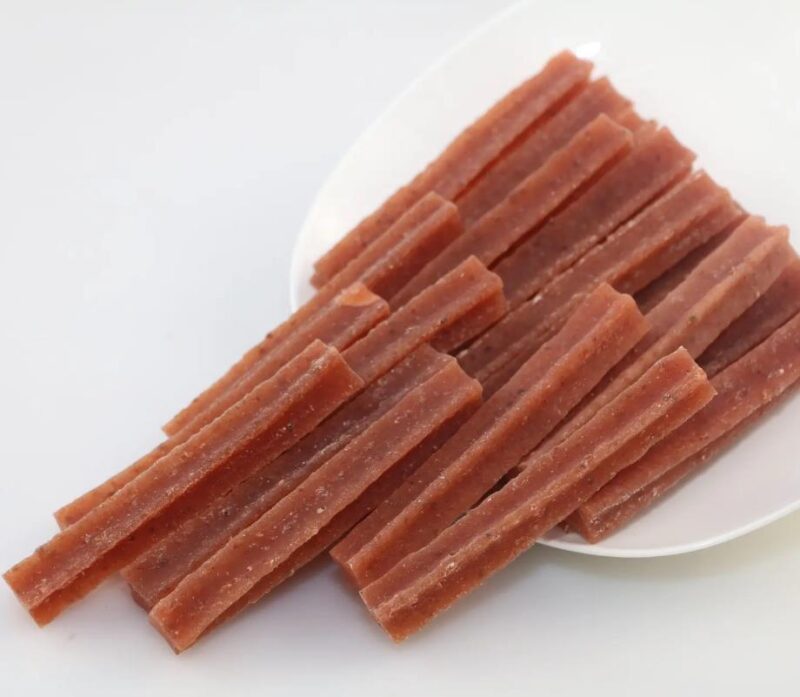

- The pellets are immediately fed into the single-screwdog food extrusion machine for further gelatinization and densitification resulting in an extrudate with a chewy/leathery texture and flexible or jerky-like properties.The extrudate is shaped in a die, and the shape options include strip, granule or sheet, etc.

- The extruded strips are rapidly cooled and solidified after the cooling process, and cut into shorts by a cutting machine.

- The semi-finished short bars are dried at low temperature and slow speed in the drying process. Drying too fast will cause pores and cracks, and drying too slowly will reduce drying effect and yield. The temperature is generally about 45 celcius, and the drying time is about 8-12 hours. During the whole process, the humidity and wind speed should also be set according to the recipe requirements.

IV. Components of 500-800 kg/h High Meat Dog Chews Food Machinery

- Fresh meat/frozen meat/bone grinder

- Pulverizing system

- Blending machine

- Storage hopper

- Twin-screw extruder 1 set

- Single-screw extruder 1 set

- Chiller

- Drying oven

- Single -drum coating system

- Oil & slurry tank

- Cooling conveyor

- Automatic packing system

- Controlling system (PLC/or instrument control options)

- Complete conveyors

- Burner

- Steam boiler (optional)

V. Features of 500-800 kg/h High Meat Dog Chews Food Machinery

- Finished Food Quality Ensured: Optimal extrusion solution, premium equipment design, and equipment processing ensure high-level and stable production.

- High Output: High designed capacity; minimal material loss;

- Less Energy: High mechanical coordination, low wear; optimized heating, thermal transfer& insulation details, low heat loss

- Low Production Cost: Flow production, precise control of each process

- Simple and Low Cost Maintenance: Modular structure, easy operation. Lifetime after-sales service

- Safe Material: High-quality food-safe materials for all food contact part

- Failure Rate: Nearly zero failure as long as preventive maintenance