The method and principle of puffing process

Although the puffing process belongs to the physical processing technology, it has its own characteristics. Puffing can not only change the shape and state of raw materials, but also change the molecular structure and properties of raw materials, and form some new substances. The puffing process is based on the principle of phase change and thermal pressure effect of gas. The liquid inside the processed material rapidly heats up and gasifies, pressurizes and expands, and relies on the expansion force of the gas to drive the structural denaturation of the polymer material in the component, thereby making it It has the characteristics of network structure and is shaped into a porous substance.Now the puff snack food produced by the food processing line is the use of this principle.

The following is a detailed introduction to his principles and methods.

Expansion mechanism

The puffing of high-temperature puffed food mainly depends on three aspects, one is the content of amylopectin in the starch raw material, the more amylopectin, the better the puffing effect; Addition of loosening agent. During the heating and drying stage of the semi-finished product, part of the leavening agent decomposes, forming a very fine porous structure in the semi-finished product, controlling the moisture to form a uniform lattice structure in the semi-finished product. In the puffing stage of the finished product, the high temperature causes the moisture in the lattice structure of the semi-finished product to evaporate rapidly, and the remaining leavening agent is heated to decompose and produce gas. The two work together to make the product reach a fully puffed puffed structure.

Classification of puffing process

According to the process conditions of puffing processing, puffing can be divided into extrusion puffing, microwave puffing, fried puffing, etc.

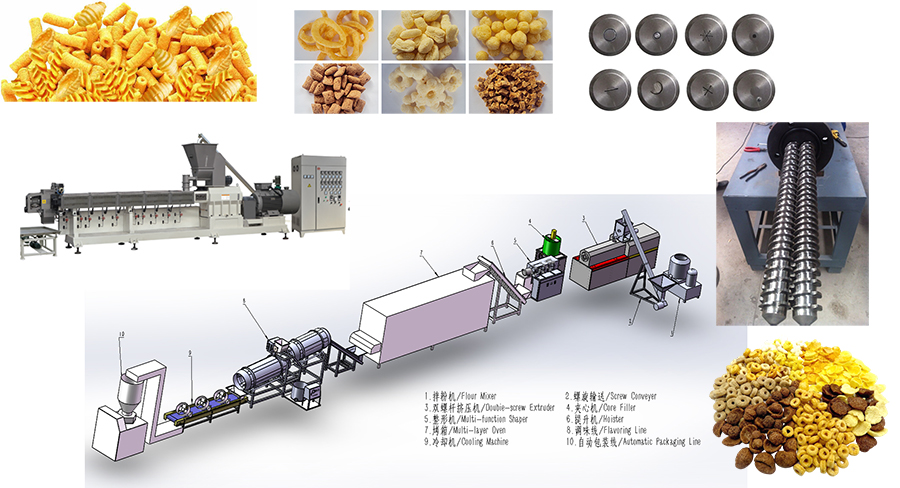

1,Extrusion puffed food processing

The puffing process of materials in the extrusion extruder can be roughly divided into three stages:

(1) Conveying and mixing stage: After the material enters the extruder from the hopper, it is propelled by the rotating screw and mixed. rise.

(2) Extrusion and shearing stage: After the material enters the extrusion and shearing stage, because the gap between the screw and the screw sleeve is further reduced, the material continues to be squeezed; when the gap is completely filled, the material is sheared ;The strong shearing principal stress causes the material agglomerate to break and produce backflow, the greater the backflow, the greater the pressure, and the pressure can reach about 1500 kPa. During this stage, the physical and chemical properties of the material change due to the strong shearing action.

(3) Extrusion and puffing stage: The material enters the extrusion and puffing stage after the temperature rise in the extrusion and shearing stage. As the gap between the screw and the screw sleeve is further reduced, the shear stress also increases sharply, and the crystal structure of the material is destroyed, resulting in a textured structure. Due to the corresponding sharp increase in pressure and temperature, the material becomes a gel state with fluidity. At this time, the material is discharged from the mold hole to the normal air pressure, and the moisture in the material evaporates and expands in an instant and cools down, so that the gelatinized starch in the material also expands, forming countless fine and porous sponges. After dehydration, the tissue structure of gelatinized starch changes significantly, the starch is fully gelatinized (a), has good water solubility, is easy to dissolve, absorb and digest, and the starch volume expands several times to ten times.

2,Microwave puffed food processing

The microwave heating speed is fast, and the temperature of the gas (air) inside the material rises sharply. Due to the slow mass transfer rate, the heated gas is in a highly pressurized state and tends to expand. When a certain pressure is reached, the material will expand.

3,Fried puffed food processing

Fried puffed food first originated in Malaysia and is a kind of crispy food that is popular in many Southeast Asian countries. With the continuous communication and penetration of the food industry of various countries in the world, this kind of fried puffed food is gradually popular in the West as a kind of flavor food.

(1) Classification of fried puffed food. It can be divided into flavor type and nutrition type. Flavor type, mainly adding various seasonings to make puffed food with different flavors such as seafood, meat, fruit, etc.; nutritional type, mainly strengthening various nutrients to improve the nutritional value of the product.

(2) The characteristics of fried puffed food. The production process is simple, the family cooking is convenient, the taste is good, easy to digest and absorb, suitable for all ages.

(3) The puffing principle of fried puffed food. During the process of gelatinization and aging, the structure of starch changes twice, first α and then β, so that the starch granules enclose water, after slicing and drying to remove part of the excess water, the superheated water in the high-temperature oil is rapidly vaporized and sprayed out. Explosion occurs, the volume of the product expands many times, and the internal tissue forms a porous, loose and spongy structure, thereby forming a puffed food.

Factors affecting product quality

1,Gelatinization

Starch granules swell and split in water at an appropriate temperature (60-80°C) to form a uniform pasty solution called gelatinization. Only starch that is fully gelatinized but not disintegrated has a large number of intermolecular hydrogen chains broken, and fully absorbs water, which is the basis for highly crystallized starch grains to enclose water in the next step of aging, thus laying the foundation for considerable puffing.

2,aging

The puffed à-starch becomes opaque starch at 2-4°C for 1.5-2 days. During the aging process, the water absorbed during gelatinization is wrapped into the microcrystalline structure of starch. When frying at high temperature, the water in the starch microcrystalline grains is rapidly vaporized and ejected, causing the starch tissue to expand and form a porous and loose structure. The purpose of puffing.

3,dry

The moisture content in the product directly affects the expansion degree of the product, so the control of the moisture content is very important. If there is too much moisture in the product after drying, it will be difficult to discharge the moisture in a short time during frying and puffing, resulting in the product not puffing up, and the taste will be soft and not brittle, which will destroy the characteristics of the product. If the moisture content is too low, it will be difficult to form enough jet steam to expand the food tissue in a short time during frying, which will also reduce the puffing degree of the product. Therefore, the drying time is selected to be about 7 hours, and the moisture content is the most suitable.

E-mail:mailto:[email protected]