350-450kg/h Oats Rings Cereal Puff Manufacturing Machine

I. Introduction of Oats Rings Cereal

The raw materials of oat rings breakfast cereal are whole grain oats flour, a certain percentage of cornstarch. Compared with other cereals, oats have high nutrition for health. The protein content of oats is the highest among cereals (the protein content in natural oats is 13%~15%). Dietary fiber content is 10 times that of rice. Unsaturated fatty acids are 5 times that of rice. Oat-based cereal rings can supplement the body’s needs with other breakfast cereals. Along the growing interests in health claims, oatmeal-based breakfast cereals are gaining traction.

Like all other breakfast cereals, in order to keep the puffed oats rings soaked in milk from breaking, it is important that the cereal rings have a finer puff texture with smaller puffed pores, so a lower gelatinization temperature is required, so apuff food extruder with longer barrel is required. In this way, the oat dough is kneaded for a longer time in the extrusion barrel to achieve the desired texrure configuration.

Besides, due to the high oil content of oats, a higher cooking energy input is required. Plus, oats are high in fiber, it doesn’t expand well. Therefore, we suggest adding a pre-conditioning process beforegrain extrusion to gelatinize the oat starch in advance.

II. Parameters of 350-450kg/h Oats Rings Cereal Puff Manufacturing Machine

| क्षमता | 350-450kg/h |

| ऊर्जा/बिजली | -बिजली का हीटिंग:

Installed power 165 kw -Other heating option (Optional): प्राकृतिक गैस/डीजल बर्नर या भाप बॉयलर |

| स्थापित क्षेत्र | आसपास 150-180 वर्ग मीटर |

| Grain material | Whole Grain Oats, Corn Starch |

III. विशेषताएं

- तैयार भोजन की गुणवत्ता सुनिश्चित की: इष्टतम बाहर निकालना समाधान है, प्रीमियम उपकरणों के डिजाइन और उपकरणों के प्रसंस्करण सुनिश्चित उच्च-स्तर और स्थिर उत्पादन.

- उच्च आउटपुट: उच्च डिजाइन क्षमता; कम से कम सामग्री के नुकसान;

- कम ऊर्जा: उच्च यांत्रिक समन्वय, कम पहनते हैं; अनुकूलित हीटिंग, थर्मल स्थानांतरण और इन्सुलेशन विवरण, कम गर्मी के नुकसान

- कम उत्पादन लागत: प्रवाह उत्पादन, सटीक नियंत्रण के प्रत्येक प्रक्रिया

- सरल और कम लागत के रखरखाव: मॉड्यूलर संरचना, आसान आपरेशन । लाइफटाइम बिक्री के बाद सेवा

- सुरक्षित सामग्री: उच्च गुणवत्ता वाले खाद्य-सुरक्षित सामग्री के लिए सभी खाद्य संपर्क हिस्सा

- विफलता दर: लगभग शून्य विफलता के रूप में लंबे समय के रूप में निवारक रखरखाव

IV. The General Flow Chart for Oat Rings Cereal Manufacturing

- Step 1: Mixing of raw materials

- Step 2: Pre-conditioning (pregelatinization for oat)

- Step 3: Extrusion of oats cereals and ring shape forming

- Step 4: Cooling

- Step 5: Pre-drying

- Step 6: Seasoning

- Step 7: Drying after seasoning

- Step 8: Cooling before packing

- Step 9: Packing

The grain cereal puff manufacturing machine work steps are as below:

- Mix the whole grain oat flour, corn starch, water and other raw materials in a certain proportion, and stir evenly.

- The mixture is loaded into the pre-conditioner to have the pregelatinization.

- Then the pregelatinized oat dough is conveyed from the pre-conditioner to a extruder with lengthened barrel. The dough is kneaded into an ideal configuration by setting a certain temperature and pressure. A ring-shape forming die is installed at the front of the After the dough is extruded from the die, the rapidly rotating blade cuts off the extrudate. Due to the pressure difference, moisture escapes, and the cut extrudate rapidly expands to circle shape.

- Then the cereal circles are dried, baked and through other processes to make them crunchy. Up to now, the plain flavor oat rings are done.

- According to market demand, the seasoning drum can be used for coating honey.

- Finally, the honey flavoroat rings are dried, cooled and packed.

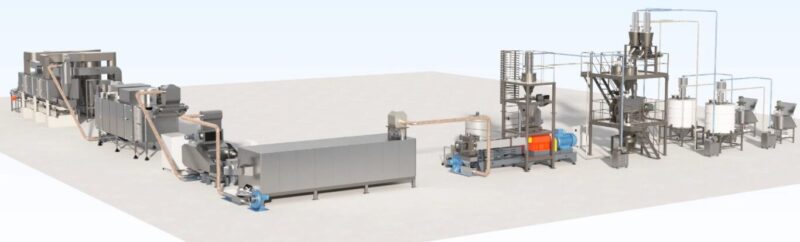

V. Components of Oat Rings Grain Cereal Puffing Machine

- मिक्सर

- Pre-conditioner

- Twin screw cereal extruder machine ( Lengthened model)

- Cooling vibrator

- Multi-layer Belt pre dryer (Electric/natural gas/diesel heating options)

- Seasoning machine

- Two-Tank syrup sprayer (Optional)

- Multi-layer Belt dryer (Electric/natural gas/diesel heating options)

- ठंडा करने की मशीन

- स्वत: पैकिंग मशीन

- नियंत्रण प्रणाली (पीएलसी/या साधन, नियंत्रण विकल्प)

- Complete conveyors (screw conveyor, air conveyor, vacuum conveyor, SS lifter, bucket conveyor etc., various to meet the solutions and factory situation)

- Other auxiliaries (like chiller, work platform, etc.)

- Steam boiler/burner (Optional according to capacity and your available energy supplying)

Puff oats loops made by Breakfast cereal machineryAs the top grain & cereal puff making machine manufacturer in China, DAYI has more than 30 साल के अनुभव in the food extrusion field, and can provide your grain food plant with:

- Optimal food solutions

- Responsible grain cereal puffing machine

- Reasonable puff machine price list

- Continuous technical support.