60-85 كجم/ساعة خبز 3D باباد الكريات آلة صنع

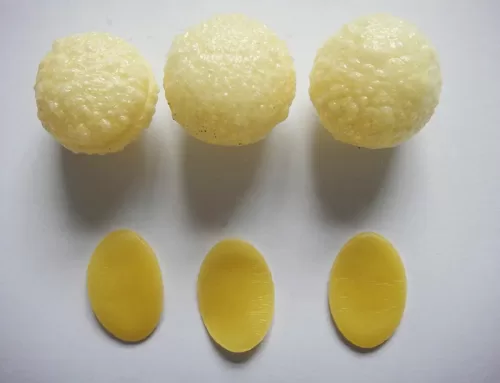

I. Introduction of Baked 3D Papad Pellets Snack

The raw material of this hexagonal grid snack pellet is corn flour. Mix corn flour and water, and you can consider adding shrimp powder/beef powder to enrich the taste and nutrition. Using advanced two-time extrusion solution, precooking with twin screw extruder first, and then realizing gelatination in single screw papad extruder machine. The gelatinized dough is extruded into a sheet of required thickness by a specially designed die. The sheet is pressed through an embossing machine to obtain the grids structure. Then pass the two grid structured sheets through a sheet combining& molding machine, the two sheets are composited together and cut into triangles/hexagons, etc., and then are dried. So far, the semi-finished bar-shaped snack particles have been completed.

Continue to puff the snack pellets (Baking)

Semi-finished grid snack pellets are conveyed into the drying equipment used in food industry. According to the output and baking effect, the baking adopts the high temperature rotary drum. By setting the roasting temperature and time, the pellets are roasted correctly. After being baked, the flat pellets get puffed. Finally, the production is completed through the seasoning and packing processes.

II. Parameters of 60-85 kg/h Baked 3D Papad Pellets Making Machine

| القدرات | 60-85kg/h |

| الطاقة/الطاقة | -التدفئة الكهربائية:

Installed power 55 kw -Other heating option: الطبيعي الغاز/الديزل من قبل الناسخ أو المراجل البخارية |

| تثبيت المنطقة | Around 100-120 square meters |

| Multigrain material | Corn/wheat/tapioca/rice/oat etc. One grain or grains combination |

III. Features

- الانتهاء من الطعام ضمان الجودة: الأمثل قذف حل ممتاز تصميم المعدات, معدات تجهيز ضمان مستوى عال ومستقر الإنتاج.

- ارتفاع الناتج: عالية الإنتاجية المصممة; الحد الأدنى من المواد الخسارة ؛

- أقل من الطاقة: ميكانيكية عالية التنسيق ارتداء منخفضة ؛ الأمثل تدفئة, النقل الحراري والعزل التفاصيل ، منخفضة فقدان الحرارة

- انخفاض تكلفة الإنتاج: تدفق الإنتاج, مراقبة دقيقة لكل عملية

- بسيطة ومنخفضة التكلفة الصيانة: هيكل وحدات ، عملية سهلة. عمر بعد-مبيعات الخدمة

- Material: عالية الجودة الغذائية-مواد آمنة لجميع الاتصال الغذاء جزء

- معدل الفشل: ما يقرب من الصفر الفشل طالما الصيانة الوقائية

IV. The General Flow Chart for Making Baked 3D Papad Pellet Snack

- الخطوة 1: خلط

- Step 2: Precooking (first extrusion)

- Step 3: Extruding & shaping (secondary extrusion)

- Step 4: Pulling

- Step 5: Embossing (grids making)

- Step 6: Combining/shaping/cutting

- Step 6: Baking

- Step 8: Seasoning

- Step 9: Cooling before packing

- Step 10: Packing

V. Components of Baked 3D Papad Pellet Snack Making Machine

- Flour mixer

- Twin screw extruder

- Single screw extruder

- مبرد

- آلة سحب

- Embossing machine

- Combining/shaping/cutting machine

- Vibration spreader

- High temperature rotary drum

- Seasoning machine

- Cooling machine

- Automatic packing machine

- نظام التحكم (PLC/أو أداة التحكم خيارات)

- كاملة سيور

- Steam boiler/Burner (Optional)

السادس. المزيد

المرونة

- Materials: This 3d papad extruder machine adopts two-time extrusion solution, which is suitable for a wide range of raw materials, such as corn flour, cassava flour, rice flour, oat flour, wheat flour and so on. It can process either multi-grain blends or single grains.

- Shapes: The mold of the composite molding machine can be changed flexibly, so that various 3D (three-dimensional) shapes can be composited, such as 3D pellets of cone shape, heart shape, racket, rectangle, Christmas tree shape, animal shape, etc.

Innovation

- When not use the embossing machine and compositing& molding machine, and use different extrusion dies, this 3d papad pellets making machine can produce 2D snack pellets like shapes of waffle/ring/short tube/animal/letter/wheel.

- In addition to snack pellets, this 3d papad making machine can also produce various other puffed baked snacks by changing molds, adding corresponding auxiliary equipment or adopting different conveying schemes: such as corn triangle chips/doritos/cheetos, cereal puff snacks etc.