350-450kg/h Wheat Flakes Breakfast Cereal Processing Equipment

I. Introduction Of Wheat Flakes

Wheat flakes are another healthy breakfast cereal besides the corn flakes and bran flakes. Its raw material is wheat flour. Wheat flour contains protein, starch, fat, vitamins and inorganic salts, and the protein content in wheat is higher than that of other cereals, generally above 11%, and even up to 15%-20%. Nutritional fortification can also be carried out by scientifically adding trace elements.

II. Parameters of 350-450kg/h Wheat Flakes Breakfast Cereal Food Making Equipment

| Capacity | 350-450kg/h |

| Energy/Power | -Electric heating:

Installed power 165kw -Other heating option (Optional): Natural gas/Diesel by burner or steam boiler |

| Installed Area | Around 150-180 square meters |

| Grain material | Wheat flour |

III. Features

- Finished Food Quality Ensured: Optimal extrusion solution, premium equipment design, and equipment processing ensure high-level and stable production.

- High Output: High designed capacity; minimal material loss;

- Less Energy: High mechanical coordination, low wear; optimized heating, thermal transfer& insulation details, low heat loss

- Low Production Cost: Flow production, precise control of each process

- Simple and Low Cost Maintenance: Modular structure, easy operation. Lifetime after-sales service

- Safe Material: High-quality food-safe materials for all food contact part

- Failure Rate: Nearly zero failure as long as preventive maintenance

IV. The General Flow Chart For Wheat Flakes Food Making Equipment

- Step 1: Mixing of wholewheat Flour & wheat bran with water

- Step 2: Extruded to pellets

- Step 3: Pellets cooling

- Step 4: Pellets flaking

- Step 5: Flakes pre-drying

- Step 6: Flakes baking

- Step 7: Flakes seasoning

- Step 8: Flakes drying after seasoning

- Step 10: Cooling before packing

- Step 11: Packing

This breakfast cereal industrial food processing equipment adopts the special extruder with extended twin screws. The specific steps of producing wheat flakes are as follows:

Combine wheat flour with water and other ingredients and stir well. The mixture is loaded into theextruder, and by setting the correct temperature and pressure, the mixture is extruded into pellets of desired size, and then the pellets are pressed into slices by rollers. The pressed pieces are dried, roasted, etc. to become crunchy. In this way, the plain wheat flake is done. According to market demand, seasoning drums can be used to sprinkle salt/sugar on plain wheat flakes. If plain wheat flakes are to be glazed, the flakes will be coated by spraying syrup or chocolate, etc. Finally, the flakes are dried, cooled and packed.

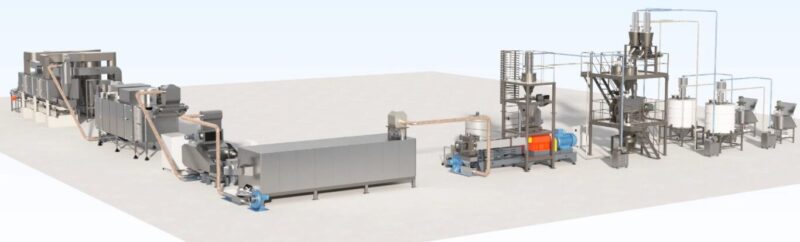

V. Components Of Wheat Flakes Industrial Food Processing Equipment

- Mixer

- Screw conveyor

- Twin-screw extruder

- Chiller

- Cooling vibrator

- Flake rolling machine

- Belt pre dryer (Electric/natural gas/diesel heating options)

- Roaster (Electric/natural gas/diesel heating options)

- Seasoning machine

- Two-Tank syrup sprayer (Optional)

- Belt dryer (Electric/natural gas/diesel heating options)

- Cooling machine

- Automatic packing machine

- Controlling system (PLC/or instrument control options)

- Complete conveyors

- Steam boiler (Optional)

- Burner (Optional)

Wheat flakes made by cereal flakes machineryAs the top industrial extrusion food making equipment manufacturer in China, DAYI has more than 30 years of experience in the food extrusion field, and can provide your grain food plant with:

- Optimal food solutions

- Responsible extrusion processing food equipment

- Continuous technical support

- Reasonable food processing equipment price