Why are more food manufacturers willing to choose vacuum conveyors in food production lines?

Vacuum conveyor, also known as vacuum feeder, uses vacuum suction to convey powder materials in a closed pipeline. When the vacuum degree of the pipeline reaches a certain level, an air pressure difference will be formed, thereby realizing automatic transportation of powder and granular materials. . Because of its high safety and long transportation distance, it is widely used in many fields, such as food, medicine, chemical industry, metallurgy and other industries.

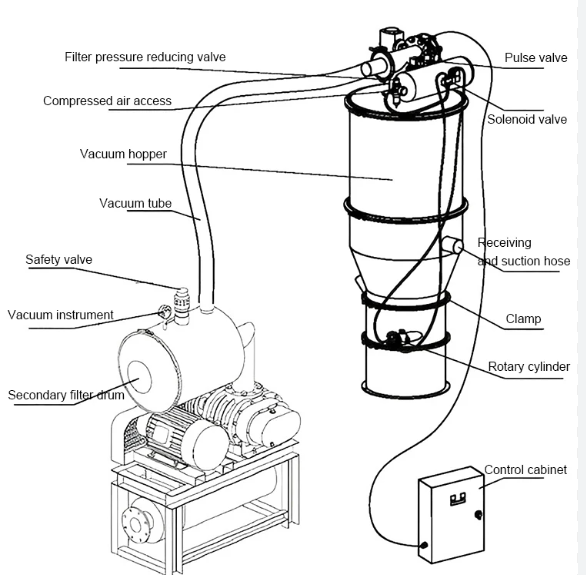

The vacuum conveyor is composed of an air compressor, filter pressure reducing valve, vacuum generator, filter, vacuum suction cup and other parts. The Roots blower is used as a vacuum source to pump air, so that the entire system and the suction nozzle are in a negative pressure state, and the powder is The material enters the feed nozzle driven by the pressure difference. Materials and gases enter the hopper through the suction pipe. After reaching the adjusted feeding time, the vacuum pump cannot generate vacuum. At the same time, the discharge door is opened, and the powder material is separated from the gas in the hopper. The gas is filtered and discharged. The separated material falls down to the receiving equipment due to gravity.

Advantages of vacuum conveyors:

- Dust-free: Adopt a closed conveying method, no powder leakage, avoid loss of materials, achieve efficient and safe conveying purposes, and prevent environmental pollution in the process.

- Flexible conveying: By adding elbows, the flow direction can be flexibly changed without being affected by height and position. The vacuum conveyor has a sensing function and will automatically stop when the silo is full, making it efficient and convenient.

- Low maintenance cost: The equipment has few wearing parts and the vacuum pump is an independent component. Without affecting the normal operation of the system, the equipment can be repaired and cleaned at low cost without disassembling the equipment. It is also easy to clean and avoids accidents. Shutdown caused the production line to stagnate.

- No pollution to materials: The conveying system has strong airtightness and can effectively prevent the external environment from contaminating materials. The conveying speed is automatically adjusted according to the characteristics of the material to avoid damage to the material.

- Small space occupied: The equipment has a compact structure and is easy to install. It can effectively take into account the actual layout and use of the workshop. The docking position of the pipe and the suction port is installed in a vertical manner, reducing the space occupied by the workshop.

- Flexible use: According to actual working conditions and process flow requirements, some parts of the conveyor can be replaced and upgraded, such as mixers, extruders, packaging machines, tablet presses, etc., which can effectively improve the overall performance of the equipment and achieve for efficient operation.

- High degree of automation: High-efficiency conveying of powders without excessive manual intervention, reducing production line staffing and improving work efficiency.

It should be noted that the vacuum conveyor is suitable for powdered or small granular raw materials. If the raw materials have high moisture and high viscosity, such as pet food ingredients mixed with meat, the advantages of the vacuum conveyor cannot be exerted due to the excessive viscosity. , you can choose bucket elevators, scraper conveyors, etc.

For more details, you can consult us at any time, and we will give you the most satisfactory food production line design plan.

For more information, please contact: