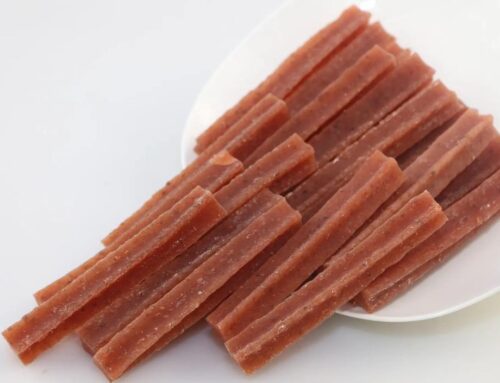

150-200kg/h CO Extrusion Dog Cat Chew Making Machine

I. Introduction of CO Extrusion Pet Chews

CO extruded pet chews typically consist of two-part extrudates from two different formulations. Each formula provides some kind of outstanding chewing effect to pets. For example, under the premise that the two parts of a CO extruded pet chew have all the basic properties expected from a chew such as long-last chewiness and good palatability, then at the same time one part of the formula may be dedicated to freshening breath, and the other part is dedicated to supplementing extra nutrients; or one part may have antibacterial effect, and the other part has the good meaty smell to increase the pet’s attention, etc.

Co-extrusion pet chews are made by co-extrusion technology. Two sets of single-screw extruders are used to handle different formulas simultaneously. The extrudates from the two dog food extruders were then co-extruded at the same die. In additiona to CO extrusion, regular single-color or single-recipe chews can be produced once the dog treat extruder is used alone.

II. Parameters of 150-200kg/h CO Extrusion Pet Chews

| Capacity | 150-200 kg/h |

| Energy/Power | -Electric heating:

Installed power 94 kw -Other heating option: Natural gas/Diesel by burner or steam boiler |

| Installed Area | 60-80 square meters |

| Material | Corn/potato starch, dry vegetable powder, dry/wet/frozen animal protein source |

III. The General Flow Chart for CO Extrusion Pet Chews Processing

- Step 1: Raw material preparation

- Step 2: Mixing

- Step 3: CO extrusion process

- Step 4: Cooling

- Step 5: Cutting

- Step 6: Drying

- Step 7: Measuring and packing

IV. Components of 150-200 kg/h Commercial Co Extrusion Dog Chews Treat Maker

- Fresh meat/frozen meat/bone grinder

- Pulverizing system

- Blending machine

- Singe-screw extruder x 2 sets

- Chiller

- Cutting machine

- Drying oven

- Cooling conveyor

- Automatic packing system

- Controlling system (PLC/or instrument control options)

- Complete conveying system

- Burner

Notice:

- Production of die-cast chews such as bones and toothbrushes requires twin-screw extrusion and vertical die-casting processes rather than CO extrusion process.

- When the content of oil and fresh meat in the raw material is high, the Secondary Extrusion Process is required: firstly use a twin-screwdog treat extruderfor precooking, and then continue to use a single-screw dog treat extruder for obtaining high density, chewy, flexible and leathery texture.

Dayi engineers will advise the most suitable commercial dog treat maker according to your needs.

V. Features of Commercial CO Extrusion Pet Chews Maker

- Finished Food Quality Ensured: Optimal extrusion solution, premium equipment design, and equipment processing ensure high-level and stable production.

- High Output: High designed capacity; minimal material loss;

- Less Energy: High mechanical coordination, low wear; optimized heating, thermal transfer& insulation details, low heat loss

- Low Production Cost: Flow production, precise control of each process

- Simple and Low Cost Maintenance: Modular structure, easy operation. Lifetime after-sales service

- Safe Material: High-quality food-safe materials for all food contact part

- Failure Rate: Nearly zero failure as long as preventive maintenance