The Enrichment Process: How Fortified Rice Becomes a Nutrient Powerhouse

The Enrichment Process: How Fortified Rice Becomes a Nutrient Powerhouse

Rice, a global staple food for billions, loses a significant portion of its inherent vitamins and minerals during milling. To combat malnutrition and dietary deficiencies, the process of rice enrichment or fortification was developed. This method systematically adds essential nutrients back into the milled grain. Here is a step-by-step breakdown of how ordinary white rice is transformed into enriched rice.

1. The Starting Point: Milled White Rice

The process begins with polished, white rice kernels. Milling removes the husk, bran, and germ to improve shelf life and cooking properties, but it also strips away crucial nutrients like iron, zinc, and B-vitamins. The resulting white rice is primarily composed of starch and has minimal natural micronutrient content.

2. Nutrient Selection and Preparation

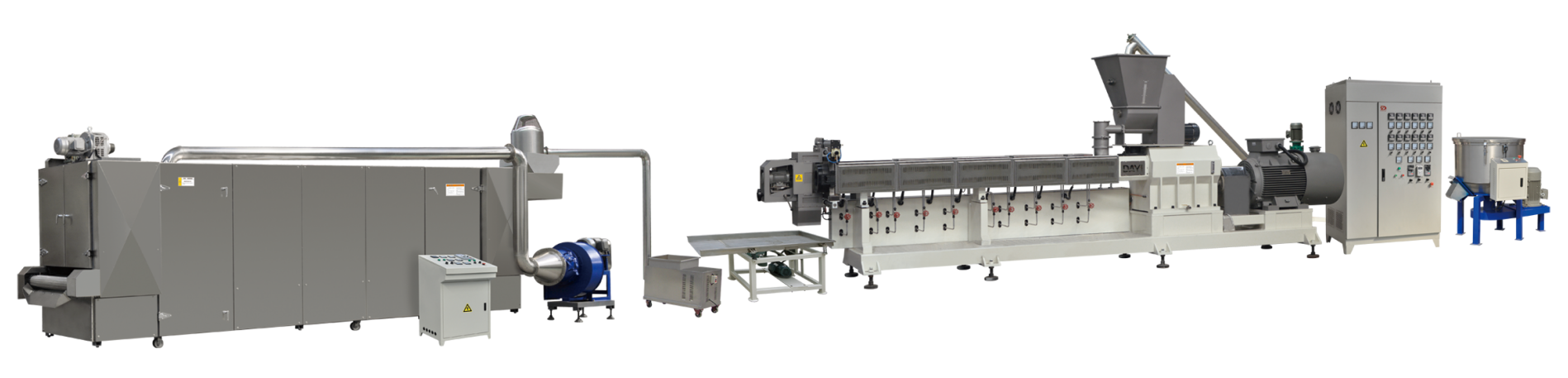

Governments and health organizations (like the WHO) establish standards for which nutrients to add and in what quantities. Fortified rice making machine A typical premix or coating powder includes:

Iron: Often as ferric pyrophosphate or electrolytic iron, crucial for preventing anemia.

Folic Acid (Vitamin B9): Vital for cell growth and preventing neural tube defects in newborns.

Thiamine (Vitamin B1): Essential for energy metabolism and preventing beriberi.

Niacin (Vitamin B3):Important for skin, nerve, and digestive health, preventing pellagra.

These micronutrients are finely ground and combined with a safe, food-grade coating agent to form a uniform powder or suspension.

3. The Core Enrichment Methods

There are several primary techniques used to apply the nutrient premix to rice kernels, each with its own advantages.

a) Coating Method (Surface Enrichment)

This is the most common and cost-effective method.

Process: Polished rice kernels are tumbled in a mixer or drum. A nutrient-rich powder, often suspended in a water or glycerin-based solution, is sprayed onto the tumbling rice.

Adhesion: The solution acts as a glue, causing the powder to adhere to the surface of the grains.

Limitation: The nutrients are only on the surface, making them susceptible to loss if the rice is rinsed or cooked in excess water.b) Dusting Method

A simpler variation of coating.

Process: The dry nutrient premix is blended directly with the dry rice in precise ratios.

Challenge: It relies on electrostatic attraction for adherence, which can be less stable. A final coating of a sealant (like a thin layer of edible wax or cellulose) is sometimes applied to “lock in” the dusted nutrients and prevent dust-off during handling.

c) Hot Extrusion (Artificial Grain Method)

This is a more advanced and durable method.

Process:Rice flour is combined with the vitamin and mineral premix and water to form a dough. This dough is then passed through an extruder—a machine that uses heat and pressure to form it into small, opaque pellets that closely resemble the shape and size of natural rice grains.

Advantage: The nutrients are embedded within the grain-like pellet, making them far more resistant to washing and cooking losses.

Blending: These artificial, nutrient-dense grains (typically at a ratio of 0.5% to 2%) are then physically blended with regular, non-fortified rice. A batch might contain 98% normal rice and 2% fortified extruded grains.

4. Quality Control and Drying

After coating or blending, the rice undergoes critical quality checks:

Nutrient Assay: Samples are tested in labs to verify that nutrient levels meet strict specifications.

Uniformity: The distribution of the coating or fortified grains is checked to ensure every serving contains the target nutrients.

Drying: For coated rice, a gentle drying step may follow to set the coating and ensure free flow, preventing clumping.

5. Packaging for Stability

The finished enriched rice is packaged in sturdy, airtight bags. The packaging is designed to protect the product from moisture, insects, and physical damage that could abrade the nutrient coating during transport and storage.

The enrichment process is a remarkable feat of food technology and public health policy. Fortified rice making machine By systematically replacing the vitamins and minerals lost during milling, it transforms a basic calorie source into a vehicle for essential nutrition. While hot extrusion offers the most resilient form of fortification, the coating method remains widely used due to its lower cost and simplicity. Regardless of the method, the goal is the same: to deliver critical micronutrients to populations in a familiar, affordable, and effective way, helping to eliminate “hidden hunger” and improve global health outcomes.

Mark

E-mail:[email protected]

whatsapp/wechat:8615953166130