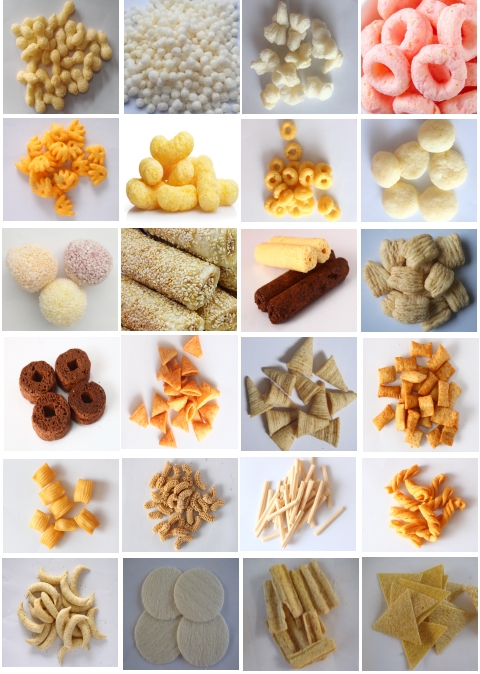

SLG85-A 400-500kg/h Puffed Crisps Snack Production Line

Introduction

- This SLG85 twin-screw extruder can produce puffed snack of around 400-500kg per hour.

- The PLC controller and touch screen bring more direct operation and monitoring experience.

- Application: various cereal puffed snacks, crisps

Production Line

| 1 | Feeding Station | Without; Feed direct into the mixer |

| 2 | Manual mixer | 100kg/batch; 6-10 minutes/batch |

| 3 | Conveyor | Screw model (for short distance transporting) |

| 4 | Extruder | SLG85 |

| 5 | Conveyor | Belt model |

| 6 | Drying machine 1 | 1 set |

| 7 | Conveyor | 1 set |

| 8 | Seasoning machine | 1 set |

| 9 | Cooler | 1 set |

| 10 | Packing machine | 1 set |

If you are planing to setup extrusion food factory, welcome to leave message below to get our advice and details.

Request A Quote

Food Solution

Tag Cloud

artificial rice machine

bread crumbs making machine

breakfast cereal machine

breakfast cereal making machine

breakfast cereal production line

cereal extruder machine

cereal extrusion

corn flakes making machine

corn puff making machine

dog food making machine

extruder snacks

extrusion snacks food machinery

flakes machine

food extruder

food extrusion machine

food factory machine

Food Production Line

fortified rice making machine

Instant rice making machine

modified starch

modified starch machine

modified starch production line

panko machine

pet food extruder

pet food machinery

pet food production line

puffed snack machine

puff machine

puff snacks processing line

snack extruder

snack extruder machine

snack food extruder

snack food machinery

snack food making machine

snack food processing equipment

snack food processing machinery

snack food production line

snacks machinery

snacks making machine

snacks manufacturing machine

snacks production machines

soya chunks making machine

tvp extruder

tvp extrusion

twin-screw extruder