जादू की कोर भरने नाश्ते मशीन

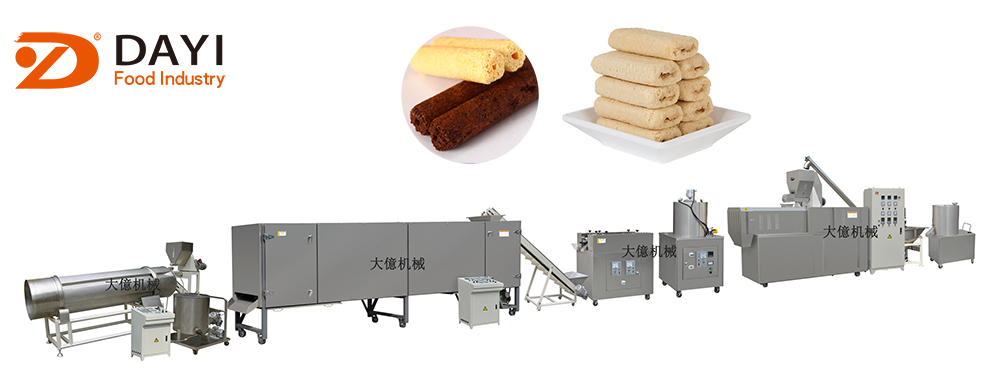

The Core filling snack production line equipment developed by Dayi Machinery is completed from raw material preparation, extrusion, sandwich, molding, cutting, spraying, seasoning to packaging of finished products at one time, with a high degree of automation, reducing manual participation.

The food production line adopts advanced co-extrusion technology to extrude two kinds of products with different textures and tastes on the twin screw host at the same time, and the core material is injected instantaneously when the extruder produces the hollow tube, which can be injected into a variety of delicious filling sauces such as peanut butter, chocolate sauce, strawberry sauce, sugar, etc., to meet the tastes of different people. Changing the mold can change the shape and size of snacks, such as: pillow shape, long strip, flat strip, heart shape and other shapes of colorful snacks, will get more children and snack lovers like. Replace the auxiliary equipment, can also produce nutrition powder, rice, corn triangle, breakfast cereal and other puffed snack food, you see, make a little change, you can easily produce another snack, increase the production line of a variety of practical value.

The puffed food has a crisp taste, easy digestion, unique flavor, convenient to carry, and is an ideal snack food in the world market. The automatic production line of core filling snack has the characteristics of “wide range of applicable raw materials, many kinds of products, convenient operation and maintenance, low energy consumption, high output” and so on.

Advantages of core filling machinery

- High production efficiency: compared with manual operation, the production efficiency of the core filling snack production line greatly improves the production efficiency, and also reduces the manual error rate in the production process.

- Strong versatility: the core filling snack production line can produce different types of products, and the type, quantity and thickness of the filling can be controlled during the production process.

- Easy operation: The core filling snack production line adopts computer control system, easy operation, and improves the stability and reliability of the production process.

- Stable product quality: The core filling snack production line can be automated, maintain product consistency and quality stability, and reduce the occurrence of variability.

Process flow: raw material preparation → mixing → extrusion → cutting → conveying → drying → oil injection → seasoning → (packaging)

Equipment configuration: mixing machine → screw feeder → twin screw expander → High elevator → cutting machine → N-layer electric oven → elevator → Oil injection machine → Roller → (packing machine)

ई-मेल:[email protected]