200-300 किलो/घंटा की रफ्तार Precooked पोषक तत्वों की भूसी पाउडर खाद्य उत्पादन मशीन

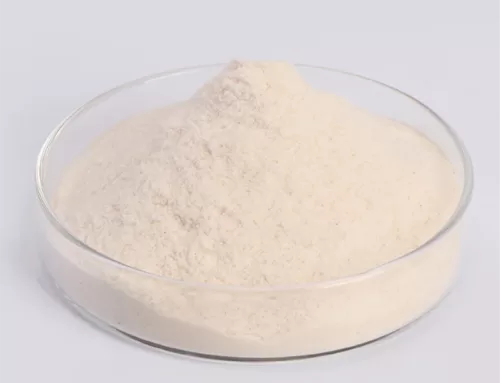

I. Introduction of Precooked Bran Nutritional Powder

Bran is the outer layer of wheat berry or oat berry. It is rich in dietary fiber, which can promote gastrointestinal motility and protect the heart.

The optimized extrusion process of the food production machine replaces the traditional grinding process. With extrusion process, wheat bran can be processed into easily digestible precooked wheat bran powder, but almost no change in crude protein content. After extrusion processing, the rough taste of wheat bran is greatly improved. Besides, the high-temperature sterilized wheat bran nutrition powder obtains a longer storage time.

II. Parameters of 200-300 kg/h Precooked Nutritional Bran Powder Food Production Machine

| क्षमता | 200-300 kg/h |

| ऊर्जा/बिजली | -Electric heating: Installed power 85 kw

-Other heating option (Optional): Natural gas/Diesel by burner or steam boiler |

| स्थापित क्षेत्र | Around 80-100 square meters |

| सामग्री | Wheat bran/oat bran combination |

III. विशेषताएं

- तैयार भोजन की गुणवत्ता सुनिश्चित की: इष्टतम बाहर निकालना समाधान है, प्रीमियम उपकरणों के डिजाइन और उपकरणों के प्रसंस्करण सुनिश्चित उच्च-स्तर और स्थिर उत्पादन.

- उच्च आउटपुट: उच्च डिजाइन क्षमता; कम से कम सामग्री के नुकसान;

- कम ऊर्जा: उच्च यांत्रिक समन्वय, कम पहनते हैं; अनुकूलित हीटिंग, थर्मल स्थानांतरण और इन्सुलेशन विवरण, कम गर्मी के नुकसान

- कम उत्पादन लागत: प्रवाह उत्पादन, सटीक नियंत्रण के प्रत्येक प्रक्रिया

- सरल और कम लागत के रखरखाव: मॉड्यूलर संरचना, आसान आपरेशन । लाइफटाइम बिक्री के बाद सेवा

- सामग्री: उच्च गुणवत्ता वाले खाद्य-सुरक्षित सामग्री के लिए सभी खाद्य संपर्क हिस्सा

- विफलता दर: लगभग शून्य विफलता के रूप में लंबे समय के रूप में निवारक रखरखाव

IV. The General Flow Chart for Precooked Bran Nutritional Powder Processing

- चरण 1: कुचल

- Step 2: Pre- conditioning

- Step 3: Extrusion (Cooking and puffing)

- Step 4: Drying

- Step 5: Crushing

- Step 6: Nutrition adding and evenly mixing

- Step 7: Measuring and packing

- Step 8: Sterilization

- Step 9: Inspection

- Step 10: Finished product

Nutritional Cereal Powder Food factory machine working process:

- The wheat bran raw material is pulverized into wheat bran powder by a pulverizer.

- To reduce the processing time of wheat bran in the extruder, the wheat bran powder is pregelatinized in the preconditioner.

- Afterwards, it is transported to thegrain extruder, and the wheat bran is homogenized, cooked, sterilized, and puffed into granules through proper temperature, pressure, and shear.

- Then it goes through a drying process to optimize the moisture content. The production of wheat bran nutritional powder is completed by pulverizing to the required precision by a superfine pulverizer.

- According to product requirements, the wheat bran powder can be seasoned and supplemented with other nutrients through the drum seasoning machine, such as mixing other coarse grain powder or adding trace elements.

- Finally, it goes through the packing and inspection process.

V. Components of precooked bran nutritional powder food processing machinery for sale

- कोल्हू

- Pre- conditioning system

- Twin screw food extruder

- शीतलन टॉवर

- Drying machine

- Drum mixing line

- कोल्हू

- Automatic packing system

- नियंत्रण प्रणाली (पीएलसी/या साधन, नियंत्रण विकल्प)

- पूरा कन्वेयर

- Burner/Steam boiler (optional)

लचीलापन

According to market demand, the process parameters can be flexibly adjusted to produce a variety of bran-based nutritional powder. For example, this food factory machine can produce branmeal of different expansion degrees (low, medium, or high), different fineness after crushing, or with different grains and nutrients additives, etc.

Versatility:

By simply adding or skipping some manufacturing steps and changing the control parameters, this food production machine can produce other nutritional grain meal, such as rice nutritional powder, oat nutritional powder, nutritional corn powder, etc.

As top food machinery manufacturer in China with more than 30 years of experience in food extrusion field, DAYI service you for your food factory with optimal food processing solution, responsible खाद्य उत्पादन की मशीन and continuous technical support.