Samples Made By Machines

The market is rapidly growing due to the combined advantages of Textured Vegetable Protein (TVP) in terms of flavor, texture, protein nutrition, and price. TVP is made of high-protein raw materials through special extrusion technology. High-protein raw materials usually include soybean meal, peanut meal, soybean protein isolate, gluten flour, etc. According to protein content in the raw material and the extrusion process, low-moisture textured vegetable protein (LM- TVP) and high-moisture textured vegetable protein (HM-TVP) can be produced.

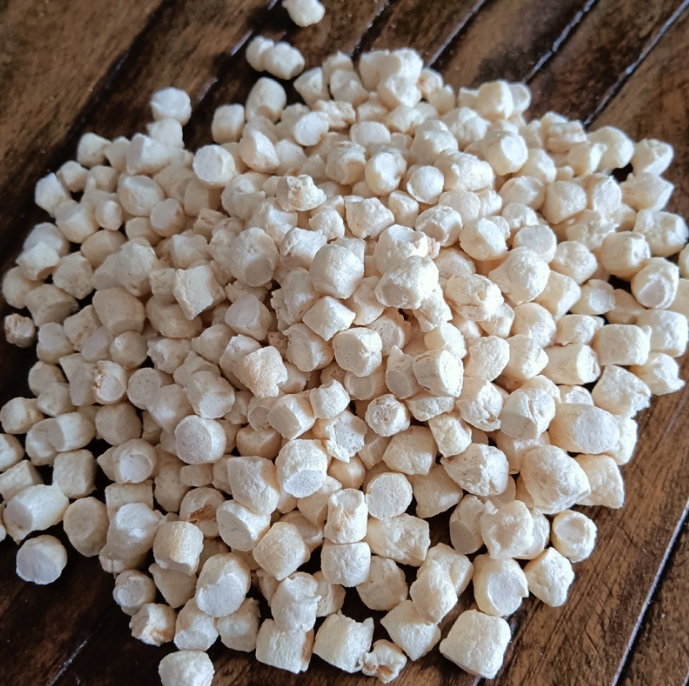

LM-TVP, the products are soya chunks/badi/nuggets, the raw materials are usually soybean meal, peanut meal, etc., which use high-temperature extrusion technology, the product has high fluffiness, crisp taste, and has a certain degree of fiber and toughness.

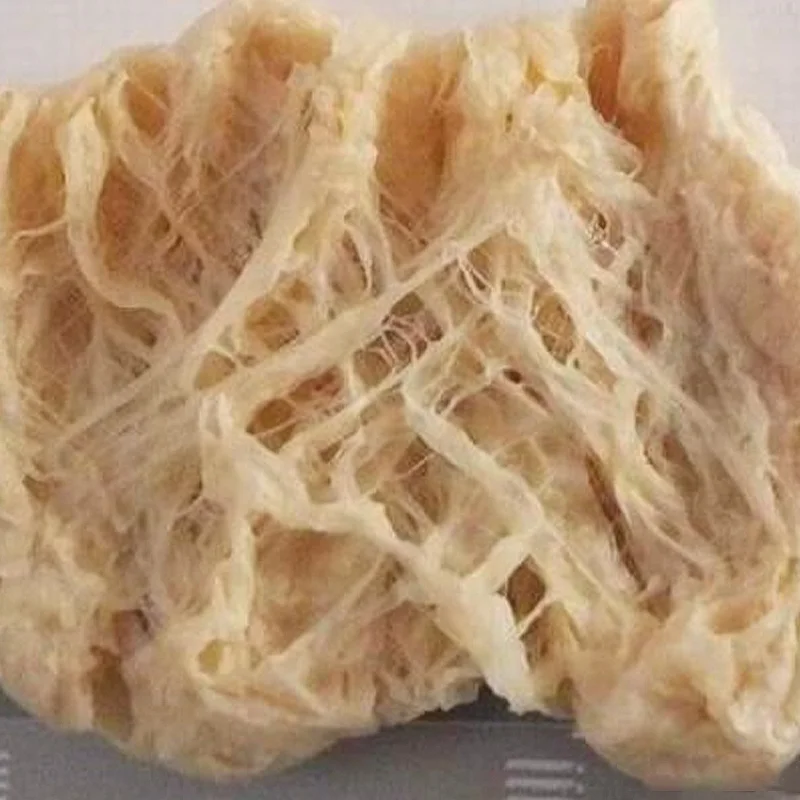

HM-TVP (also known as silk protein), the raw material is usually a mixture of soybean protein isolate and gluten powder. It uses a low-temperature and high moisture extrusion technology, and the finished product has high water content and high fiber content, and is juicy which is closer to the taste of meat.

In addition to protein source, process parameters that affect the properties of textured vegetable proteins (chewiness, toughness, hardness) are: moisture content, feed rate, temperature, shear strength, die pressure, die temperature and other specific mechanical properties. Our TVP production line is designed and manufactured according to your TVP texture requirements to achieve the most effective production. Whether you need a machine, or whole soya chunks/badi/nuggets/high moisture extrusion making line machine, or expand your production capacity, we have the advantages of professional knowledge and production experience to escort you.

Textured vegetable protein production process:

Ingredients→Mixing→Conditioning→Extrusion→Forming→Crushing→Screening→Drying→Cooling→Packing

Application: low-moisture textured vegetable protein (LM- TVP), high-moisture textured vegetable protein (HM-TVP)

| Output | Installed Power | Installed Space (m) | Food |

| 100-150 kg/h | 90 kw | ||

| 200-300 kg/h | 101 kw | 21(L) x 2.2(W) x 3.1(H) | Textured soy/peanut/wheat protein; soy chunks/badi/nuggets |

| 400-500 kg/h | 265 kw | 28(L) x 3(W) x 5.3(H) | |

| 1000 kg/h | 390kw | 35(L) x 3(W) x 5.3(H) | |

| 250-300 kg/h

(full automation) |

304 kw | 61(L) x 6.5(W) x6.5(H) | Edible meat-analogue protein |

Request A Quote

Get Your Proposal

Best Food Solution

Subscribe For Offers

Subscribe for early access offers, discounted rates, and you can cancel at any time.