Comprehensive understanding of industrial edible modified starch(2/2)

After starch is modified, what are the advantages and characteristics of modified starch?

There are mainly the following categories:

1 gelatinization temperature

The conventional starch gelatinization temperature is 60-70°C. We can change the gelatinization temperature by denaturing starch according to our needs. For example, for some products, I need them to have a low gelatinization temperature and be easy to cook. We need to lower their gelatinization temperature by denaturing the starch. There are some products that I need to be resistant to cooking, shearing, and able to withstand high temperature environments. In this case, we need to increase the gelatinization temperature of the starch.

2 Hot and cold viscosity

Conventional starch will change greatly after being cooked. The texture will be thinner when hot, but will become very thick after cooling, and may even gel. For common products such as sauce, we need it to have a very stable viscosity, and its temperature viscosity does not change much even after cooling. This is what we require. The hot and cold temperatures will keep the viscosity relatively stable. I can achieve this through denaturation.

3 Freeze-thaw stability

Nowadays, many quick-frozen foods need to be stored frozen. Using conventional starch, there is no problem at room temperature. However, if they are thawed after freezing, they will age and become dregs. This is because of poor freeze-thaw properties. However, through denaturation, the freeze-thaw stability of starch will be very strong, that is, before freezing, after freezing, and after thawing, it will still maintain its original paste shape and always maintain its original taste.

4 Water retention and anti-aging properties

Some products use starch to lock in moisture, reduce the growth of microorganisms, and reduce tissue damage. Another one is anti-aging. After some products are produced, they may have a shelf life of 7 days or 15 days. Over time, they will become hard and the taste will deteriorate. If you want to achieve a long shelf life, traditional starch thickening cannot achieve it. To achieve this effect, modified starch can improve the anti-aging properties of the product. By adding different modified starches, we can meet our requirements.

What are the uses and applications of modified starch?

1 Pasta & instant food

For example: rice noodles, udon noodles, instant noodles

2 Quick frozen food

Pasta, pastries, glutinous rice balls, dumplings

3 Condiments

Seasonings such as oyster sauce, abalone juice, chicken juice, chili sauce, tomato sauce, etc. require the thickening stability of modified starch.

4 Meat products

It has a thickening and smooth taste effect on fish balls, meatballs, sausages, ham and other meat products.

5 Sauces

Some sauces commonly found in buns, such as custard sauce, salad dressing, jam, and some sandwich sauces used in baked pastries, etc.

6 Sweets and drinks

For example, we are often late for gummies, marshmallows, etc.; yogurt also uses modified starch to achieve a thickening effect.

Modified starch is used in a wide range of applications. Basically, if you want to improve the quality or taste of food, you can use modified starch.

How much is added?

Add appropriate amounts according to national food safety standards and product needs.

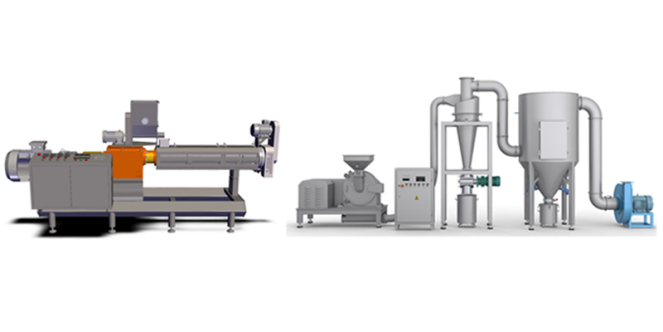

For more information about modified starch and modified starch production lines, please contact us

For more information, please contact: