Automatic puffed rice cake making machine

Advanced, automatic puffed rice cake making machine, can produce corn flavor, pumpkin flavor, onion flavor and other kinds of rice cake. This rice biscuits machine can be made to different tastes. We[...]

What are the health benefits of eating fortified rice

Fortified rice, also known as nutrient-fortified rice, refers to the finished rice made by adding some nutrient-fortified rice to ordinary rice. At present, the main nutrients used for rice nutrition[...]

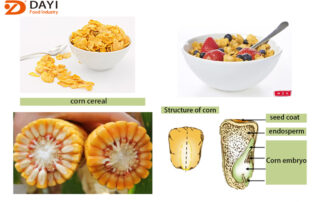

Raw materials and finished products of breakfast cereal corn flakes

Corn flakes is a new type of fast food, which has a long storage time and is easy to carry. It can be eaten directly or processed into other foods.[...]

What You Should Know as a Fortified Rice Manufacturer

Global Fortified Rice Market According to relevant research reports, the global fortified rice market size is expected to grow at a CAGR of 6.5% during the period 2021-2028 and may[...]

The difference between fish feed in pellet process and extrusion process

In early aquaculture, moist natural products such as low-value fish or waste from slaughterhouses and fisheries were used as food sources. The preparation of this feed does not require very[...]

Why are soy protein nuggets so popular?

Do you know how soy protein nuggets are eaten? Let's talk about: 1 Meat substitutes: Soy protein cubes are often used as meat substitutes in food processing because their tissue[...]

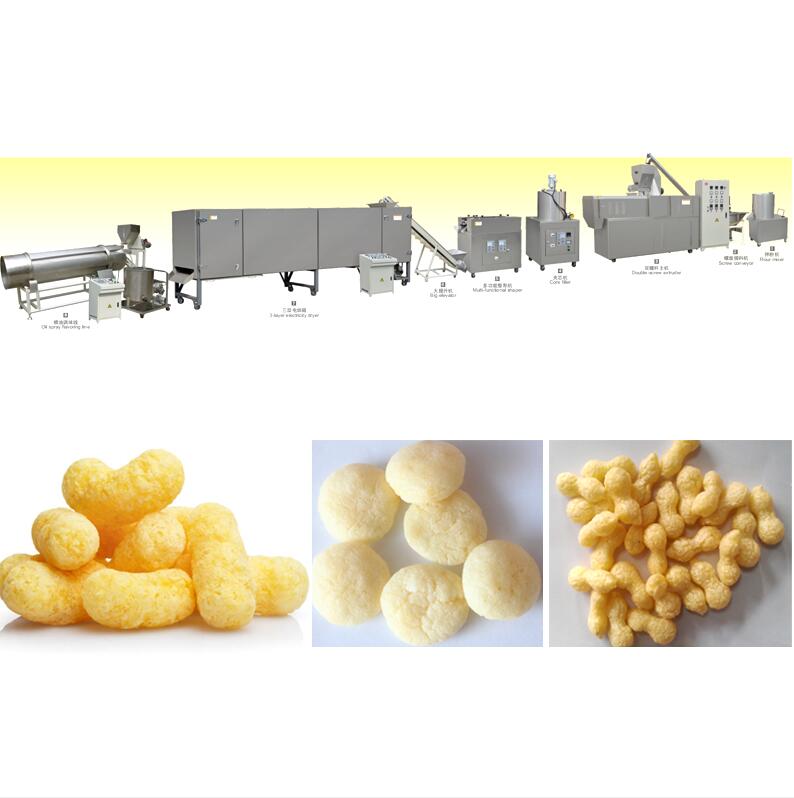

The magic of the Core filling snack machine

The Core filling snack production line equipment developed by Dayi Machinery is completed from raw material preparation, extrusion, sandwich, molding, cutting, spraying, seasoning to packaging of finished products at one time, with[...]

Some things About FRK(Fortified Rice Kernels)

What is fortified rice kernels? Fortified rice kernels are kernels of rice that right blend with vitamins and minerals, as well as other micronutrients. The role of fortified rice kernels ? Fortifying rice with[...]

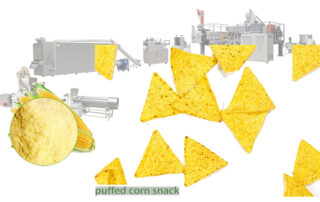

The difference between wet puffing and dry puffing of corn

There are many factors affecting corn puffing, the main reasons are moisture content, puffing temperature, puffing pressure, etc., which are also several factors that can be controlled in the current[...]

How to maintain extruded food production line machinery?

1.Daily cleaning: food processing equipment will appear in the production of food residues, in order to food safety, the inside of the equipment needs to be cleaned regularly, the outside[...]

Popcorn production and machinery

Popcorn is the perfect transformation of corn A popcorn seed can pop out of its shell in an instant and become more popular than a corn kernel. With the mini[...]

Elevator in snack food production line

In a variety of large extruded food production lines, the elevator is an indispensable equipment. This machine is a machine for automating production. It can transport raw materials to the[...]

Drying machine in snack food production line

Multi-layer belt dryer in food industry is a commonly used continuous equipment used in drying process, which can be widely used in chemical, food, medicine, building materials, electronics and other industries.[...]

Snack food seasoning drum machine

Seasoning drum machine, also known as snack food seasoning machine, is mainly used for mixing seasoning powder and raw materials in the later stage of food processing. Its application range includes[...]

snack food continuous fryer

Continuous frying machine is the main model of frying process application in fried snack food production line, and it is also an indispensable frying equipment for mechanized large and medium-sized food processing plants, such[...]

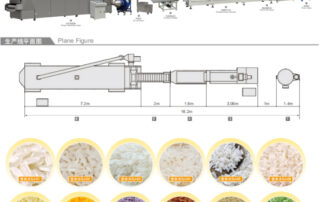

How does an artificial rice machine make rice?

Artificial rice making machine using broken rice, corn, millet, wheat, oats, buckwheat, beans, starch as the main raw materials, some other vitamins and minerals as part of the raw materials first[...]

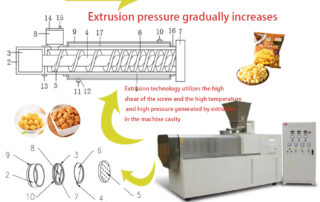

Twin screw extruder and single screw extruder different practicality

Usage differences Twin-screw extruder generally produces food without a lot of extrusion pressure. The extrusion pressure of twin-screw extruder is not as good as that of single-screw extruder, which is[...]

Selection of fish feed production equipment

Feed bulking technology is mainly used in the production of special aquatic feed, pet feed and other animal feed. In addition to the advantages of the general full price pellet[...]

The characteristics of floating fish feed and how to choose floating fish feed making machine

With the rapid development of aquaculture industry, its economic benefits have been quite considerable, so a variety of aquatic feed, especially floating fish feed particles came into being. Because the[...]

Production of pre-gelatinized starch using screw extrusion technology

Do you know which plants are high in starch? Starchy plants tend to be carbohydrate-rich foods, as well as root vegetables. For example: rice, corn, wheat, root vegetables include: potatoes,[...]

The difference and function of pregelatinized starch and modified starch

The difference between pregelatinized starch and modified starch Generally speaking, pregelatinized starch is a kind of modified starch with relatively simple processing and wide application, that is to say, pregelatinized[...]

Modern extruding technology of bread crumb

Bread crumb is widely used as a food accessory in life, especially in the frying process, such as usually fried chicken pieces, fried chicken legs, fried onion rings can be used, fried food[...]

The change of nutritional composition of food during extrusion

The high temperature of the food processing environment in the extrusion process will also exert greater pressure on the relevant raw materials, both of which will cause damage or reorganization[...]

What is dog chews and the role of dog chews?

Dog chews is a pet toy or food. Its shape is usually different shapes such as bones, balls, circles, sticks and shoes. This is a chewing agent designed specifically for dogs[...]