How is TVP Made

Definition Plant protein meat is also called vegetarian meat, artificial meat, and meat analogs. It is a meat-like food processed using advanced modern food processing technology. Artificial meat is currently[...]

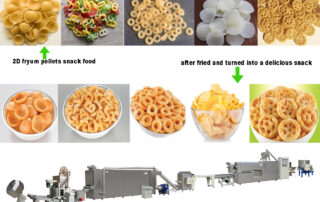

You can quickly and clearly understand the processing process of extruded food

Different product types have different processing processes, but for extruded foods, the processing processes of different products have many similarities. Let's talk about the general process of extruded food production[...]

Seasoning system in puffed food production line

After the extruded puffed food has gone through the drying or cooling stage, it needs to be seasoned to have different special flavors. This process method is a very convenient[...]

How to clean the screw in the twin-screw extruder?

After the extruder screw stops, the die head needs to be removed. Note that the extruder is still very hot at this time, and the disassembly personnel should wear heat-insulating[...]

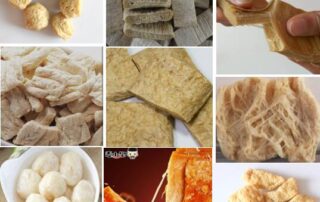

Dry Meat Analogue Brushed TVP Mnuafacturing Process

Dry Meat Analogue Brushed TVP Mnuafacturing Process Dry Meat Anolog, also called Brushed Protein. It's a kind of TVP (textured vegtable protein). But it's texture is much more similar to[...]

Production and application of acetate starch

Acetate starch is composed of starch and acetate esterification agent. Its production process is to mix starch and acetate esterification agent through esterification reaction. Raw materials for making acetate[...]

Comprehensive understanding of industrial edible modified starch(2/2)

After starch is modified, what are the advantages and characteristics of modified starch? There are mainly the following categories: 1 gelatinization temperature The conventional starch gelatinization temperature is 60-70°C.[...]

Comprehensive understanding of industrial edible modified starch(1/2)

How much do you know about industrial edible modified starch? What performance does it have? You definitely know about starch, but do you know what modified starch is? Today[...]

How to choose food production line?

When choosing a food production line, there are several key factors to consider: Product structure First of all, you need to understand the basic structure of the product, including[...]

How are breakfast cereals made? -Cocoa filling snack food

Cocoa filling snack is one of the more popular snacks in modern times. It can be eaten as snack food or mixed with milk and eaten as breakfast cereal. It is both[...]

How to produce higher-end corn flakes ?

I. How to satisfy modern people who want convenient and healthy breakfast food? Corn flakes are a good choice. Corn is known as the golden grain. It is rich in[...]

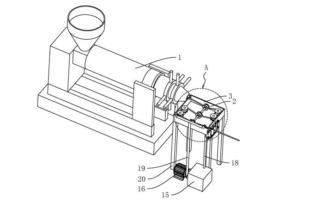

Twin Screw Extruder Vs Single Screw Extruder

Twin Screw Extruder Vs Single Screw Extruder Here we introduce more about the Types of extruders used in food industry. I. Single screw extruder The single screw extruder has a simple[...]

The Function of Preconditioner in Feed Processing:

The main functions of preconditioner are: The conditioner greatly increases the gelatinization degree of starch under the action of water and heat, which is beneficial to animal absorption; at the[...]

Why are more food manufacturers willing to choose vacuum conveyors in food production lines?

Vacuum conveyor, also known as vacuum feeder, uses vacuum suction to convey powder materials in a closed pipeline. When the vacuum degree of the pipeline reaches a certain level, an[...]

Differences among various textured vegetable proteins

Differences Among Various Textured Vegetable Proteins Textured vegetable protein is also called TVP, or meat analogue. It is a kind of healthy food nowadays, and can be cooked into various[...]

Things you need to know before starting a dog food factory

Research and development of high-quality dog food brands: there are a variety of dog food brands on the market, and the quality is uneven. In order to be successful and[...]

DAYI food extrusion machine new upgrade

In every food production line, the extruder plays a vital role as a host in the entire production line, and the technological innovation of the extruder is the core key[...]

The main processes of extruded food processing

Product varieties are different, the processing process is different, but for extruded food, the processing process of different products has many similarities, its working process is: (1) Mixed multiple[...]

Composition of food extrusion equipment

Food extrusion equipment in addition to the extruder - host, but also have auxiliary machinery and control system Main engine A food extruder (host) is mainly composed of[...]

Extrusion production technology of snack food

Extrusion technology can be used to process a variety of snack food and snack food, fried, there are non-fried; There are low water directly expanded, there are high water molding[...]

Extrusion food features

The processing process of extruded food is completely different from the cooking and curing process of ordinary food processing, and the heating, curing and extrusion molding of extruded food are[...]

How does the overload protection of the extruder work?

In order to ensure that the extruder does not damage the motor and extrusion screw when overloaded, the transmission part and electrical part of the extrusion screw are usually provided[...]

Different categories of extruded foods

At present, a variety of extruded food on the market has been unknowingly accepted by people, but which food is extruded food, many consumers are not clear, which requires extruded[...]

Characteristics of food extrusion process

The processing of food essentially refers to a series of physical and chemical changes that occur during the processing of various raw material molecules. Extrusion cooking is an operation in[...]