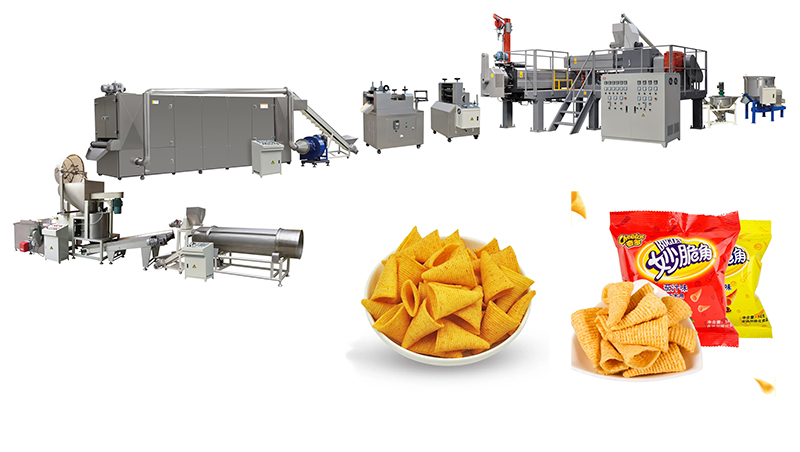

Automatic bugles chips corn snacks manufacturing machine

Bugles production line takes wheat flour, corn flour, wheat flour or other mixtures as raw materials, adopts twin-screw extrusion technology instead of traditional steam cooking process, the whole bugles mechanical production line includes mixing, cooking, extrusion, frying, seasoning, molding and other processes, without boiler, simple process and high efficiency. Low carbon pollution. The machine has self-cleaning, multi-function, high efficiency, easy operation, large production capacity, suitable for new leisure food production line and expand production scale, have production experience of the factory.

The bugles chips making machine can change the mold and molding machine, cutting machine to change the shape, such as strip, wavy square, diamond, pillow, triangle, gourd shape, fish cake, etc., Like the more popular corn triangle, tortilla chips,doritos, kurkure, Cheetos, the processing makeing machine can be achieved by changing the formula, mold and forming machine.

this taste crisp not greasy, nutritious, easy to digest the structure of the snack is loved by many people around the world. And most importantly, the waste punching chips can be reused after being ground into powder, which can greatly reduce production costs.

Advantages of industrial horn sheet production line

(1) Frequency conversion speed regulation, high degree of automation.

(2) Smooth operation and long service life.

(3) The material is made of alloy steel and special technology.

(4) Long service time, high pressure, long screw life.

(5) Self-cleaning function, can be cleaned without disassembly when shut down.

(6) With automatic temperature control system, temperature control is more intuitive, more accurate parameters.

Our services

- Free consultation service before, during and after sale;

- Free project planning and design services;

- Free debugging equipment until everything is normal;

- Free management of long-distance transportation of equipment;

- Free training on equipment maintenance and personal operation;

- Provide new production technology and formula free of charge;

- Provide 1 year full warranty and lifetime maintenance service.

Our honor

- Engineers can be sent overseas to repair machinery

“DaYI” brand enjoys a high reputation in the global and domestic market, the products are exported to more than 50 countries and regions, with strong design strength, advanced production technology and rich manufacturing experience, the company’s products have been praised by customers at home and abroad.

As a professional supplier of bugles snack food manufacturing machines, our fried snack machines are designed with good manufacturing processes and unlimited innovation in raw materials. The technology department of the company continues to develop and innovate according to market demand, and has never stopped to improve and upgrade the equipment according to customer requirements.