250-300 كجم/ساعة الرطوبة العالية قذف بمادة البروتين النباتي آلة صنع

I. Introduction of High Moisture Extrusion Vegetable Protein

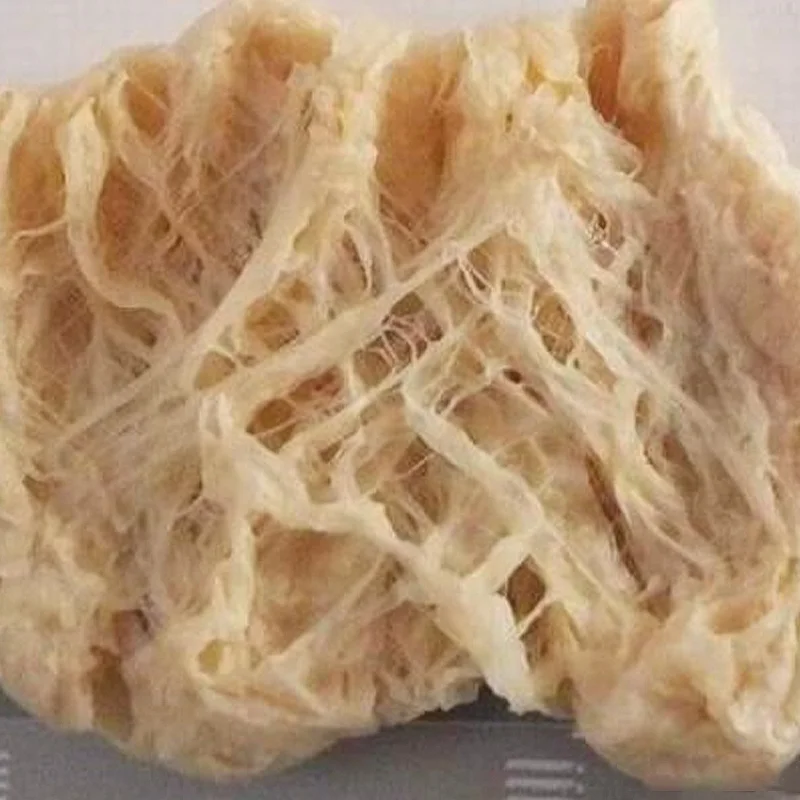

High moisture textured vegetable protein (also called HM-TVP) has a more obvious filamentous fiber structure than any other plant textured protein. Its fibrous structure is tightly arranged, which is more in line with the characteristics of meat. There is no need for secondary rehydration during use.

By matching different vegetable protein sources and grains, the HM-TVP production line can produce various plant-based meat analogs which resembles the desired fibrous-structure, bite and juicy mouth-feel, such as fifish meat, muscle meat, beef meat, etc.

The extrusion process of wet textured vegetable protein requires more water and oil, and the water is usually 50%-70%. Extrusion temperature needs be lower. It is therefore necessary to configure cooling channels to the extruder barrel – the protein mixture is extruded through a long cooling slit die (20-80ºC) to prevent moisture evaporation and thus maintain high moisture in the extrudate. After extrusion, the extrudate does not need to be dried, but refrigerated or frozen , or continued for further processing, such as seasoning and packing.

II. Parameters

| القدرات | 250-300 kg/h |

| الطاقة/الطاقة | -التدفئة الكهربائية:

Installed power 304 kw -Other heating option: الطبيعي الغاز/الديزل من قبل الناسخ أو المراجل البخارية |

| تثبيت المنطقة | Around 400-500 square meters |

| المواد | Single or combined material of defatted soya protein/wheat protein/peanut protein/pea protein etc. |

III. Features

- الانتهاء من الطعام ضمان الجودة: الأمثل قذف حل ممتاز تصميم المعدات, معدات تجهيز ضمان مستوى عال ومستقر الإنتاج.

- ارتفاع الناتج: عالية الإنتاجية المصممة; الحد الأدنى من المواد الخسارة ؛

- أقل من الطاقة: ميكانيكية عالية التنسيق ارتداء منخفضة ؛ الأمثل تدفئة, النقل الحراري والعزل التفاصيل ، منخفضة فقدان الحرارة

- انخفاض تكلفة الإنتاج: تدفق الإنتاج, مراقبة دقيقة لكل عملية

- بسيطة ومنخفضة التكلفة الصيانة: هيكل وحدات ، عملية سهلة. عمر بعد-مبيعات الخدمة

- مواد آمنة: عالية الجودة الغذائية-مواد آمنة لجميع الاتصال الغذاء جزء

- معدل الفشل: ما يقرب من الصفر الفشل طالما الصيانة الوقائية

IV. The General Flow Chart for High Moisture Extrusion Vegetable Protein

- Step 1: Crushing

- Step 2: Mixing

- Step 3: High moisture extrusion process with cooling

- Step 4: Seasoning(optional, it’s to produce flavoured textured veggie protein)

- Step 5: Cooling before packing

- Step 6: Packing

V. Components of High Moisture Extrusion Vegetable ProteinProduction Line

- Crusher

- Flour mixer

- Lengthened twin-screw extruder

- مبرد

- Vibration spreader

- Seasoning machine(optional, it’s to produce flavoured textured veggie protein)

- Cooling machine

- Automatic packing machine

- نظام التحكم (PLC/أو أداة التحكم خيارات)

- كاملة سيور

- Diversity

The twin screw wet extrusion process can produce various fiber-structured vegetable proteins, with a wide range of raw materials including soybean protein, peanut protein, wheat protein, pea protein, sunflower protein, special protein, etc. Vegetable protein powder can also be mixed with other ingredients, such as tea polyphenols, rice, etc., to produce the HM-TVP that highlights certain properties.

- المرونة

The quality of high-moisture vegetable protein fibrous structure depends on extrusion parameters. It includes temperature, moisture, feed rate, barrel temperature, shear, die pressure, die temperature and other processing parameters, which can be flexibly realized by setting on control system for different recipes.

- Various shape options

By changing different extrusion dies, you can produce high-moistured textured plant protein in various shapes, such as blocks, sheets, strips, etc. Dayi provides mold customization service.