800-1000 kg/h Textured Peanut Food Processing Equipment

I. Introduction of Textured Peanut Protein

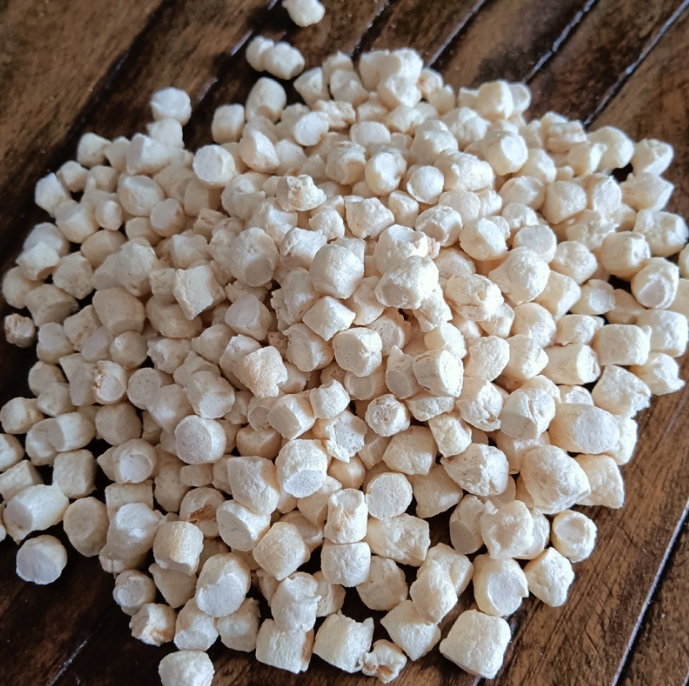

Textured peanut protein is a type of TVP (textured vegetable protein). Its main raw material is cold-pressed peanut cake or peanut meal, also known as defatted peanut meal (Peanut cake is a by-product of peanut oil produced by cryogenic pressing technology, and its high-quality protein content is as high as 50%). Compared with textured soyabean protein, the textured peanut protein has the advantages of whiter color, no beany smell, finer texture, and being friendly to the stomach.

Extrusion process is one of the important method to produce TVP. The texture of the crushed peanut-cake or peanut meal changes under required pressure, temperature and shear of the twin screw food extruder, and is puffed into protein puffs with desired elasticity and toughness. By setting the process parameters of the tvp extruder, TVP with different moisture, extrusion degree and shape can be accurately realized. Textured peanut protein produced by the correct extrusion process has fast rehydration speed, high water absorption and expansion, and is juicy after rehydration.

II. Parameters of 800-1000 kg/h Peanut TVP Food Processing Equipment

| Capacity | 800-1000 kg/h |

| Energy/Power | -Electric heating:

Installed power 255 kw -Other heating option: Natural gas/Diesel by burner or steam boiler |

| Installed Area | Around 150-180 square meters |

| Material | Defatted peanut cake/meal |

III. Features

- Finished food quality ensured: Optimal extrusion solution, premium equipment design, and equipment processing ensure high-level and stable production.

- High output: High designed capacity; minimal material loss;

- Less energy: High mechanical coordination, low wear; optimized heating, thermal transfer& insulation details, low heat loss

- Low production cost: Flow production, precise control of each process

- Simple and low cost maintenance: Modular structure, easy operation. Lifetime after-sales service

- Material: High-quality food-safe materials for all food contact part

- Failure rate: Nearly zero failure as long as preventive maintenance

IV. The General Flow Chart for Peanut TVP Food Processing

- Step 1: Crushing

- Step 2: Mixing

- Step 3: TVP Extrusion & cutting

- Step 4: Drying (to reduce the water content to 8%)

- Step 5: Seasoning(optional, it’s to produce flavoured textured veggie protein)

- Step 6: Cooling before packing

- Step 7: Packing

1)The crusher makes the peanut cake into powder. The mixer blends peanut protein powder and other ingredients evenly. The recipe can be supplemented with a certain proportion of soybean/ wheat protein powder to optimize the resulting texture.2) The extrusion process can be conducted in a standard twin screw extruder of food processing equipment. The dry protein powder mixture is fed at a constant rate, while water is added to the extruder too. The mixture moisture content should be less than 50%. 3) Set the temperature of the heating and cooling areas, the screw speed, pressure on the tvp extruder, and the extrusion process starts. Due to the rapid temperature and pressure changes in the extrusion barrel, the food product expands rapidly as it exits the extrusion die, creating a crunchy and airy texture. 4) The protein puff is then transferred to the oven for drying. Depending on the output and desired final moisture content, the oven is designed as single or multiple-layer. By setting the drying temperature and resting time, semi-finished peanut textured protein is dried correctly.

V. Components of 150-300kg/h Textured Peanut Protein Processing Equipment

- Crusher

- Flour mixer

- Twin-screw tvp extruder

- Chiller

- Vibration spreader

- Dryer

- Seasoning machine(optional, it’s to produce flavoured textured veggie protein)

- Cooling machine

- Automatic packing machine

- Controlling system (PLC/or instrument control options)

- Complete conveyors

- Burner/Steam boiler (Optional)

VI. More

Flexibility

- The quality of peanut TVP fibrous structure depends on extrusion parameters including temperature, moisture content, feed rate, barrel temperature, shear, pressure & temperature at die and other mechanical properties. For example, the extrusion moisture affects the tensile and elastic properties of peanut TVP, which can be devided into dry peanut TVP and low-wet peanut TVP. By adjusting all these extrusion parameters of the food extruder, different formulations can be flexibly realized, the operation is convenient, the texture is uniform and continuous production is possible.

Diversity

- The twin screw food processing extruder is applicable to a wide range of raw materials, including soybean protein powder, wheat protein powder, and pea protein powder, so as to produce various TVP proteins; Other raw materials, such as starch can be supplemented to optimize the strength, elasticity and fibrosis of TVP.

Multiple shapes

- By changing different extrusion dies, you can produce TVP in various shapes, such as chunks/nuggets/badi, flakes, strips, balls, pellets, etc. Dayi provides custom mold service.

As an extrusion food equipment manufacturers with more than 30 years of experience in the global market, DAYI service you for your grain food plant with optimal food extrusion engineering, responsible food equipment and trustworthy technical support.