What potential economic profits will high-quality machinery bring you after using it?

Before purchasing a food production line, food manufacturers often consider two issues: price and quality. Every customer wants to buy a low-priced, high-quality machine, but the quality of the equipment[...]

60-85 kg/h Baked 2D Snack Pellets Production Machinery

I. Introduction of Baked Pellet Snacks (Waffle/Pipe/Screw/Animal/Letter/Wheel chips) Pellet snacks are made from the snack pellets through a secondary puffing process. Snack pellets are a kind of semi-finished snacks. They can be[...]

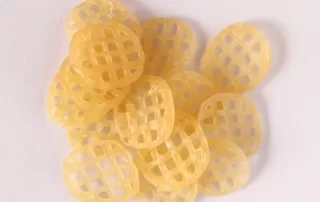

100-150kg/h Fried Shell Extrusion Snack Food Processing Machinery

I. Introduction of Fried Shell Snack The fried shells are made of wheat flour supplemented with cornstarch. It is made by the extrusion snacks food machinery. 1) Grain flour and other ingredients[...]

100-150kg/h Baked Wavy Multigrain Chips Making Machine

I. Introduction of Oven Baked Wavy Chips Baked wavy multigrain chips are made with a variety of grains, including whole corn flour, whole wheat flour, black rice flour and whole oat[...]

100-150kg/h Co-extrusion Coarse Rice Bar Puffed Snacks Machinery

I. Introduction of Co-extrusion Coarse Rice Bar Co-extrusion coarse rice bar consists of two parts: the shell outside and the sandwich inside. The raw material for the puffed grain shell[...]

How does the snacks making mahcine make corn puff ?

Puffed snacks have the characteristics of crisp taste, easy digestion, changeable taste and shape. It is widely popular with young and old all over the world. Among them, corn puff is the[...]

Different puffed methods of snack food

The so-called puffed food is mainly made of grains, potatoes or beans as raw materials, and is made by pressurizing, heating or extrusion, which changes the internal structure and volume of[...]

5 common snack puffing techniques

1 Extrusion technology: extrusion extrusion is through the snack extruder external force on the food raw materials to do work, so that the temperature of the food rises, forming a high temperature[...]