Extrusion production technology of snack food

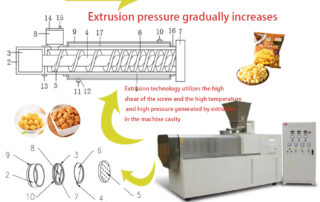

Extrusion technology can be used to process a variety of snack food and snack food, fried, there are non-fried; There are low water directly expanded, there are high water molding[...]

60-85 kg/h Baked 2D Snack Pellets Production Machinery

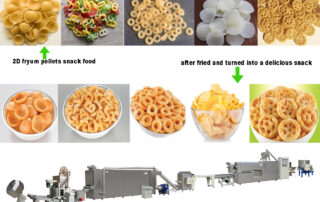

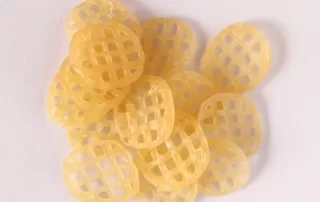

I. Introduction of Baked Pellet Snacks (Waffle/Pipe/Screw/Animal/Letter/Wheel chips) Pellet snacks are made from the snack pellets through a secondary puffing process. Snack pellets are a kind of semi-finished snacks. They can be[...]

100-150kg/h Fried Potato Stick Namkeen Snacks Making Machine

I. Introduction of Potato Sticks This fried stick snack is made from a combination of grains (wheat flour, rice flour, corn flour and potato flour). With this snack food making machine, the cereal[...]

The change of nutritional composition of food during extrusion

The high temperature of the food processing environment in the extrusion process will also exert greater pressure on the relevant raw materials, both of which will cause damage or reorganization[...]

Answers to common questions about snack food machine and our services

Answers to frequently asked questions Q: What is the output of this snack production line? A: Since each machine has several models, we will match the production line for[...]

SLG85-A 400-500kg/h Puffed Crisps Snack Production Line

Introduction This SLG85 twin-screw extruder can produce puffed snack of around 400-500kg per hour. The PLC controller and touch screen bring more direct operation and monitoring experience. Application: various cereal[...]