60-85 kg/h Baked 2D Snack Pellets Production Machinery

I. Introduction of Baked Pellet Snacks (Waffle/Pipe/Screw/Animal/Letter/Wheel chips) Pellet snacks are made from the snack pellets through a secondary puffing process. Snack pellets are a kind of semi-finished snacks. They can be[...]

100-150kg/h Co-extrusion Coarse Rice Bar Puffed Snacks Machinery

I. Introduction of Co-extrusion Coarse Rice Bar Co-extrusion coarse rice bar consists of two parts: the shell outside and the sandwich inside. The raw material for the puffed grain shell[...]

The change of nutritional composition of food during extrusion

The high temperature of the food processing environment in the extrusion process will also exert greater pressure on the relevant raw materials, both of which will cause damage or reorganization[...]

Advantages of twin-screw extruder in the snack food processing industry

Extrusion is a common feed and food processing technique that involves the use of a series of screws (or a single screw) to push food into small troughs, which are[...]

5 common snack puffing techniques

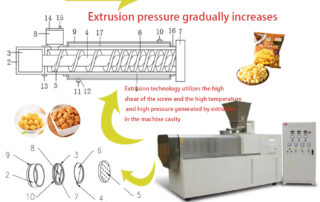

1 Extrusion technology: extrusion extrusion is through the snack extruder external force on the food raw materials to do work, so that the temperature of the food rises, forming a high temperature[...]

Extrusion principle and technology

Extrusion principle Materials containing a certain amount of water are pushed by the screw in the extruder barrel, blocked by the mold and cutting device in the barrel, and are[...]