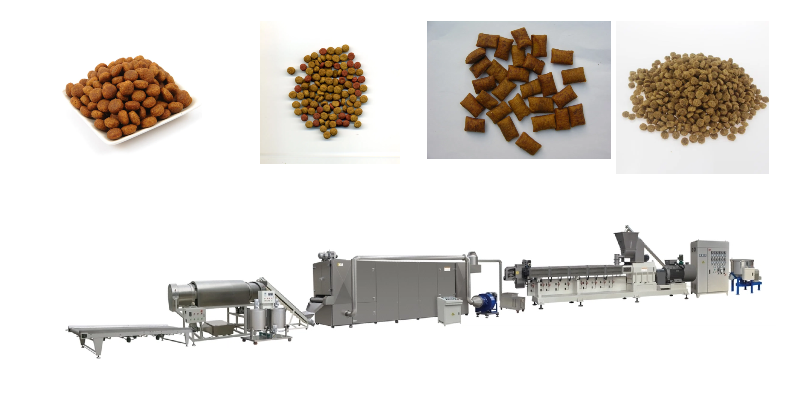

How to make different shape of dog food ?

The Production Process of Puffed Dog Food

Puffed dog food is a popular type of pet food known for its light, crunchy texture and high digestibility. The production process involves several steps to ensure the final product is nutritious, safe, and appealing to dogs. Here’s an overview of how puffed dog food is typically made:

Ingredients:

– High-quality protein sources (e.g., chicken, beef, fish, or plant-based proteins)

– Carbohydrates (e.g., corn, rice, wheat, or potatoes)

– Fats and oils (e.g., chicken fat, fish oil, or vegetable oils)

– Vitamins and minerals

– Fiber sources (e.g., beet pulp, cellulose)

– Optional: flavor enhancers, preservatives, and colorants

Equipment:

– Mixer

– Grinder

– Extruder

– Dryer

– Coating drum

– Packaging machine

Production Steps:

1. Ingredient Selection and Preparation:

– High-quality ingredients are selected based on nutritional requirements and safety standards.

– Raw materials are cleaned and ground into a fine powder to ensure uniformity.

2. Mixing:

– The ground ingredients are mixed in a large mixer to create a homogeneous blend. This ensures that each piece of dog food contains a balanced mix of nutrients.

– Water or steam may be added to the mixture to achieve the desired moisture content.

3. Extrusion:

– The mixed ingredients are fed into an extruder, which is the key machine in the puffed dog food production process.

– Inside the extruder, the mixture is subjected to high temperature and pressure. This process cooks the ingredients and transforms them into a dough-like consistency.

– As the dough passes through the extruder die, it expands rapidly due to the sudden drop in pressure, creating the characteristic puffed texture.

4. Drying:

– The puffed pieces are then transferred to a dryer, where they are dried to reduce moisture content. This step is crucial for ensuring the shelf stability of the product.

– The drying process also helps to harden the pieces, giving them their crunchy texture.

5. Coating:

– After drying, the puffed pieces may be coated with fats, oils, or flavor enhancers in a coating drum. This step improves the palatability of the dog food and adds extra nutrients.

– The coating is evenly distributed to ensure each piece is flavorful and appealing to dogs.

6. Cooling:

– The coated pieces are cooled to room temperature to stabilize the product and prepare it for packaging.

7. Quality Control:

– Throughout the production process, quality control measures are implemented to ensure the final product meets safety and nutritional standards.

– Samples are tested for moisture content, nutrient levels, and potential contaminants.

8. Packaging:

– The finished puffed dog food is weighed and packaged in bags or containers.

– Packaging is designed to protect the product from moisture, air, and contaminants, ensuring it remains fresh and safe for consumption.

9. Storage and Distribution:

– Packaged dog food is stored in a cool, dry place before being distributed to retailers or directly to consumers.

Wnioski:

The production of puffed dog food is a complex process that combines science and technology to create a nutritious and appealing product for dogs. By carefully selecting ingredients and controlling each step of the process, manufacturers can produce high-quality puffed dog food that meets the dietary needs and preferences of pets.

Email:[email protected]

whatsapp:8615953166130