How can you make modified starch achieve the desired effect after mixing with cold water?

After modified starch is processed by an extruder, its physical, chemical and structural properties will change significantly, which is mainly related to the high temperature, high pressure, high shear force and mechanical action during the extrusion process. The following are the main changes and effects of modified starch during extrusion processing:

- Structural changes

- Starch gelatinization and crystal structure destruction

- Żelatynizacja: The high temperature (usually 100–200°C) and high pressure during the extrusion process cause starch granules to absorb water and swell, hydrogen bonds to break, the crystal structure to disintegrate, and the starch molecules to change from an ordered arrangement to a disordered gel state.

- Crystal type transformation: The A-type (cereal starch) or B-type (tuber starch) crystals of natural starch may be partially transformed into a more stable V-type (amylose-lipid complex), affecting solubility and digestibility.

- Molecular degradation and reorganization

- Molecular chain breakage: High shear force may cause the degradation of starch molecules (amylose and amylopectin), reduce molecular weight, generate dextrin or small molecular sugars, and reduce viscosity.

- Cross-linking or reorganization: Some modified starches (such as cross-linked starches) may further cross-link during extrusion to enhance thermal stability; while other types may rearrange their molecular chains to form new network structures.

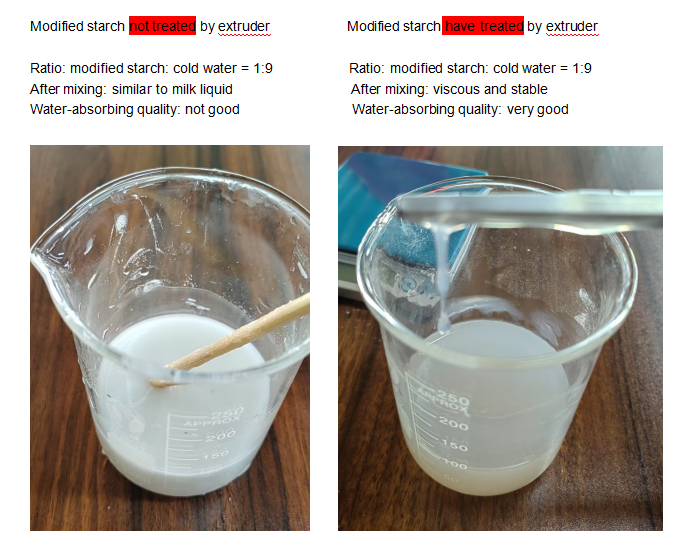

Modified starch mixed with cold water

- Changes in physical properties

- Solubility and swelling capacity

- The water solubility of gelatinized starch increases, and cold water solubility may increase (especially pregelatinized starch).

- The formation of a porous structure after extrusion may increase water absorption, but excessive degradation may lead to a decrease in swelling capacity.

- Rheological properties

- The viscosity decreases significantly (due to molecular degradation), but the gel strength may increase due to reorganization, depending on the starch type and extrusion parameters (such as temperature and moisture content).

- Morphology and texture

- After extrusion, the starch presents a porous, flaky or fibrous structure with a looser texture, which may be used to make puffed foods or as a carrier material.

- Changes in chemical properties

- Chemical group reaction

- The original chemical modification groups (such as acetyl and hydroxypropyl) of the modified starch may be partially decomposed due to high temperature, affecting functional properties (such as freeze-thaw stability).

- Maillard reaction (if protein coexists) or oxidation reaction may occur, resulting in color change (browning).

- Resistant starch (RS) formation

- Recrystallization of amylose during extrusion may form resistant starch (RS3 or RS4), which increases dietary fiber content and reduces glycemic index.

- Changes in functional properties

- Thermal stability and mechanical properties

- The high temperature resistance and shear capacity of cross-linked starch may be further improved, making it suitable for high-temperature processed foods.

- The film-forming or fiber-forming properties of starch after extrusion may be enhanced, and it can be used in biodegradable packaging materials.

- Digestive properties

- Increased rapidly digestible starch (RDS): Gelatinization makes starch more susceptible to enzymatic hydrolysis.

- Resistant starch (RS) formation: Some restructured structures may resist digestion, depending on processing conditions (such as low moisture extrusion promotes RS formation).

(3) Adsorption and carrier function

- The porous structure can increase the loading capacity of flavor substances and active ingredients, and is often used in microencapsulation or drug sustained release systems.

- Application Impact

The modified starch after extrusion processing performs better in the following fields:

- Food industry: ready-to-eat food, puffed snacks, flavoring carrier.

- Medical field: controlled release drug carrier, disintegrant.

- Environmentally friendly materials: degradable plastics, packaging films.

- Feed processing: improve starch digestibility or as a binder.

Key regulatory factors

The extrusion effect is affected by the following parameters:

- Temperatura: high temperature promotes gelatinization and degradation, low temperature may retain some crystal structure.

- Moisture content: high moisture (20–30%) is conducive to gelatinization, low moisture promotes molecular degradation and porous structure

- Screw speed and shear force: high shear force aggravates molecular breakage.

- Starch type: linear/branched ratio, modification method (acetylation, cross-linking, etc.) determine the final properties.

Summary

Extrusion processing significantly changes the structure and function of modified starch through physical-chemical synergy, making it more suitable for high value-added applications. By adjusting the process parameters, the gelatinization degree, molecular weight distribution, digestibility and other properties of starch can be controlled to meet different industrial needs. If you have any questions, please contact us.

For more information, please contact: