350-450kg/h Fruit-Shape Cereal Puff Food Making Machine

I. Introduction of Fruit-Shape Puffed Cereal

Fruit-shape breakfast cereals add pleasure to people while providing nutrition. The raw material is combination of corn flour and rice flour or other grain flours, rich in nutrition.

In this breakfast cereal puff food industry making machine, the extrusion dies of the food extruder are specially designed. So after the cereal dough is extruded from the corresponding dies, it rapidly expands into the desired fruit shapes, such as lemon, orange, banana, and flowers, through pressure difference. The puff shapes are standard and beautiful, and the color is bright, matching the fruits characteristics. Various colors can be obtained by using either natural colors or safe artificial colors.

Like all other breakfast cereals, in order to make the puffed fruit-shaped cereals soaked in milk not to break, it is important that the cereals have a finer puff texture with smaller puffed pores, so a lower gelatinization temperature is required, so an extruder with longer barrel is required. In this way, the cereal dough is kneaded for a long time in the cereal extrusion cylinder to achieve the desired configuration.

II. Parameters of 350-450kg/h Fruit-Shape Cereal Puff Food Making Machine

| القدرات | 350-450kg/h |

| الطاقة/الطاقة | -Electric heating: Installed power 165kw

-Other heating option (Optional): Natural gas/Diesel by burner or steam boiler |

| تثبيت المنطقة | Around 150-180 square meters |

| Grain material | Corn flour/whole grain corn , rice flour/rice; |

III. Features

- الانتهاء من الطعام ضمان الجودة: الأمثل قذف حل ممتاز تصميم المعدات, معدات تجهيز ضمان مستوى عال ومستقر الإنتاج.

- ارتفاع الناتج: عالية الإنتاجية المصممة; الحد الأدنى من المواد الخسارة ؛

- أقل من الطاقة: ميكانيكية عالية التنسيق ارتداء منخفضة ؛ الأمثل تدفئة, النقل الحراري والعزل التفاصيل ، منخفضة فقدان الحرارة

- انخفاض تكلفة الإنتاج: تدفق الإنتاج, مراقبة دقيقة لكل عملية

- بسيطة ومنخفضة التكلفة الصيانة: هيكل وحدات ، عملية سهلة. عمر بعد-مبيعات الخدمة

- مواد آمنة: عالية الجودة الغذائية-مواد آمنة لجميع الاتصال الغذاء جزء

- معدل الفشل: ما يقرب من الصفر الفشل طالما الصيانة الوقائية

IV. The General Flow Chart for Fruit-Shape Cereal Puff Making

- Step 1: Mixing of raw materials

- Step 2: Cereal extrusion and forming

- Step 3: Cooling

- Step 4: Pre-drying

- Step 5: Blending

- Step 6: Seasoning

- Step 7: Drying after seasoning

- Step 8: Cooling before packing

- Step 9: Packing

The specific steps to produce fruit-shaped breakfast cereals with extrusion technology are as follows:

- Mix rice flour, corn flour(or other grain flour such as oat flour, wheat flour, etc.), water and other raw materials in a certain proportion, and stir evenly.

- The mixture is loaded into the lengthened extruder, and is kneaded into ideal dough by setting a certain temperature and pressure. Fruit shapeforming die is installed at the exist of the extruder.

- After the dough is extruded from the die, the rapidly rotating blade cuts off the extrudate. Due to the pressure difference, moisture escapes, and the cut extrudate rapidly expands to desired fruit

- Then the cereal pieces are dried, baked and other processes to make them crunchy. Up to now, the plain flavor fruit breakfast cereal is done.

- According to market demand, the seasoning drum can be used for the seasoning process.

- Finally, the seasoned fruit cereals are dried, cooled and packed.

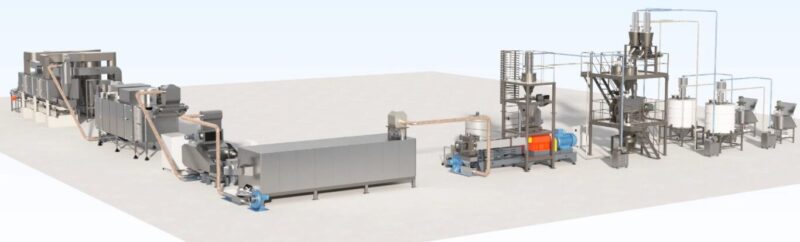

V. Components of 100-160kg/h Fruit-Shape Cereal Puff Making Machine

- خلاط

- المسمار الناقل

- Twin-screw extruder (corn/wheat/other grain puff making machine)

- مبرد

- Cooling vibrator

- Belt pre dryer (Electric/natural gas/diesel heating options)

- Blending drum

- Seasoning machine

- Two-Tank syrup sprayer (Optional)

- Belt dryer (Electric/natural gas/diesel heating options)

- Cooling machine

- Automatic packing machine

- نظام التحكم (PLC/أو أداة التحكم خيارات)

- كاملة سيور

- Steam boiler /burner (Optional)

Fruit shape puffs made by breakfast cereal machineAs the top puff food industry factory machine manufacturer in China, DAYI has more than 30 عاما من الخبرة in the food extrusion field, and can provide your grain food plant with:

- Mature food plant solutions

- Responsible food factory puff making machine

- Continuous technical support

- Reasonable puff food making machine cost