300-500kg/h عالية لحم الكلب يمضغ الطعام يجعل آلة

I. Introduction of High-Meat Dog Cat Chews

The secondary extrusion process is specially designed for high meat content cat and dog chews. When the content of fat and fresh meat in the raw material is high, because the moisture and fat in the raw animal raw material will offset the friction in the extruder barrel, making it difficult or even impossible to reach a proper cooking temperature, a twin-screw + single-screw secondary continuous extrusion molding process is required: firstly use a twin-screw cat/dog food extruder for precooking, and then continue to use a single-screw cat/dog food extruder for obtaining high density, chewy, flexible and leathery texture.

Notice:

Dayi engineers will advice the most suitable dog chews food making machine according to your needs.

- When producing bone-shaped, toothbrush-shaped and other die-casting chews, twin-screw extrusion and die-casting processes are required.

- When it is necessary to combine two formulas or colors into one chew, co-extrusion process is required.

- For ordinary single-color or single-recipe pet chews, the single-screw extrusion process is enough.

II. Parameters of 300-500kg/h High-Meat Dog Chews Food Making Machine

| القدرات | 300-500 kg/h |

| الطاقة/الطاقة | -التدفئة الكهربائية:

Installed power 187 kw -Other heating option: الطبيعي الغاز/الديزل من قبل الناسخ أو المراجل البخارية |

| تثبيت المنطقة | 145 square meters |

| المواد | Corn/potato/wheat/rice starches, dry vegetable powder, dry/wet/frozen animal protein source |

III. The General Process Flow Chart of High-Meat Dog Chews Food Machine

- Step 1: Raw materials preparation (degreasing, grinding etc.)

- Step 2: Mixing

- Step 3: First extrusion

- Step 4: Secondary extrusion

- Step 5: Drying

- Step 6: Oil coating and flavor seasoning

- Step 7: Cooling

- Step 5: Measuring and packing

The working process of the secondary continuous cat/dog chews food making machine is as follows:

- Mix evenly the crushed meat products, grain starch (sometimes gluten-free starch), vegetable gum and other raw materials (fruit puree, plant tissue, etc.).

- The mixture is fed into the twin-screw extruder at a constant speed. The twin-screw dog food extruder self-wipes, co-rotates and intermeshes in the multiple processing zones, thereby thoroughly mix the product. Then the cooked and shaped extrudate from the twin-screw dog food extruderis then cut into pellets.

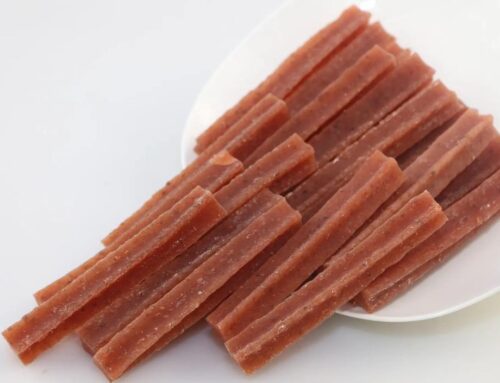

- The pellets are immediately fed into the single-screwdog food extrudermachine for further gelatinization and densitification resulting in an extrudate with a chewy/leathery texture and flexible or jerky-like properties. The extrudate is shaped in a die, and the shape options include strip, granule or sheet, etc.

- The extruded strips are rapidly cooled and solidified after the cooling process, and cut into shorts by a cutting machine.

- The semi-finished short bars are dried at low temperature and slow speed in the drying process. Drying too fast will cause pores and cracks, and drying too slowly will reduce drying effect and yield. The temperature is generally about 45 celcius, and the drying time is about 8-12 hours. During the whole process, the humidity and wind speed should also be set according to the recipe requirements.

IV. Components of 300-500 kg/h High-Meat Dog Chews Food Making Machine

- Fresh meat/frozen meat/bone grinder

- Pulverizing system

- Blending machine

- Storage hopper

- Twin-screw dog chews food extruder 1 set

- Single-screw dog chews food extruder 1 set

- مبرد

- Drying oven

- Single -drum coating system

- Oil & slurry tank

- Cooling conveyor

- التلقائي نظام التعبئة

- نظام التحكم (PLC/أو أداة التحكم خيارات)

- كاملة سيور

- Burner

- Steam boiler (optional)

V. Features of 300-500 kg/h High-Meat Dog Chews Food Making Machine

- الانتهاء من الطعام ضمان الجودة: الأمثل قذف حل ممتاز تصميم المعدات, معدات تجهيز ضمان مستوى عال ومستقر الإنتاج.

- ارتفاع الناتج: عالية الإنتاجية المصممة; الحد الأدنى من المواد الخسارة ؛

- أقل من الطاقة: ميكانيكية عالية التنسيق ارتداء منخفضة ؛ الأمثل تدفئة, النقل الحراري والعزل التفاصيل ، منخفضة فقدان الحرارة

- انخفاض تكلفة الإنتاج: تدفق الإنتاج, مراقبة دقيقة لكل عملية

- بسيطة ومنخفضة التكلفة الصيانة: هيكل وحدات ، عملية سهلة. عمر بعد-مبيعات الخدمة

- مواد آمنة: عالية الجودة الغذائية-مواد آمنة لجميع الاتصال الغذاء جزء

- معدل الفشل: ما يقرب من الصفر الفشل طالما الصيانة الوقائية